Water swelling rubber waterstop bar is made from water swelling rubber water line on the basis of the ordinary rubber water-stop. The concrete waterstops swell when contact with the structures and increased the tightness between them which improved water stop and waterproof performance and also solved the problem of circle seepage which puzzled people long term. This series rubber water stops have been used widely in some key projects and got excellent results.

Product Detail

Application

The Water swelling bar from Yongxi can be widely applied to various types of concrete structures, such as: dams, reservoirs, subway, culverts, tunnels and other underground works.

Classification

According to shape water swelling bar can be divided into "rubber putty type (BW type)"and"rubber product type(PZ type) " ( unvalcaization and vulcanization). We can select according to different demand of water-proof construction.

1) BW water-swellable waterstop bar(rubber putty type )which will expand when water go in, is a new type of seal material. It can effectively resolve the sealing problems of settlement joints of concrete structures.

The BW water-swellable waterstop bar with high Inflation rate, the mobile complementary is strong. Have stronger balance self-healing function when in the construction joints. Concrete waterstops can block of new tiny cracks caused by settlement, for completed projects, such as aperture infiltration water, can be used to be leaked.

| No | Item | Index | |

| 1 | Tensile strength/MPA≥ | 3 | |

| 2 | Elongation at break/%≥ | 350 | |

| 3 | Expansion rate in volume/% | 200 | |

| 4 | Repeated water immersion test | Tensile strength/MPA≥ | 3 |

| Elongation at break/%≥ | 350 | ||

| Expansion rate in volume/% | 200 | ||

| 5 | Low temperature bending(-20°C*2h) | No crack | |

2) PZ water-swellable rubber waterstop bar (rubber product type)

It is vulcanized, but different from ordinary rubber products. Concrete waterstops have good resilience and ductility, and has elastic sealing and water stop effect. Expansion in water and water stop in water, and the water stop effect is more reliable than that of ordinary water stop materials.

| No | Item | Index | ||||

| PZ-150 | PZ-250 | PZ-400 | PZ-600 | |||

| 1 | Hardness (shore) | 42±7 | 45±7 | 48±7 | ||

| 3 | Elongation at break/%≥ | 450 | 350 | |||

| 4 | Expansion rate in volume/% | 150 | 250 | 400 | 600 | |

| 5 | Repeated water immersion test | Tensile strength/MPA ≥ | 5 | 12 | ||

| Elongation at break/%≥ | 350 | 250 | ||||

| Expansion rate in volume/% | 150 | 250 | 300 | 500 | ||

| 6 | Low temperature bending(-20°C*2h) | No crack | ||||

Product Features

1. Water swelling rubber waterstop bar has good elasticity, ductility, extend ability and water stop performance. The swelling rate in water can be adjusted between 100% and 500%. The expansion volume retains the elasticity and extension capacity of rubber and the expansion capacity of rubber, and the expansion rate is not affected by water quality.

2. Water swelling rubber waterstop bar still has good water stopping performance in the wide

temperature range and perfect weather resistance.

3. Water swelling rubber waterstop bar has good water resistance, chemical medium resistance and durability;

No harmful substances, no swelling and precipitation, no pollution to the environment.

4. Water swelling rubber waterstop bar could be manufactured into any shape in accordance with end user's requirements, and also be made with common rubber into a composite water proof material.

Installation

1) For concrete construction joint interface after hardening, sweeping away the dross, dust, and other debris, expose the hard base.

2) Construction of the late poured band and horizontal construction joint, the water swelling strip along the extension direction of construction joint, using its own adhesive paste directly in the middle position of construction joints, joint lap joint is not less than 5cm, and shall not leave the breakpoint; for vertical construction joint shall be set aside, positioning and shallow groove, the sealing strip embedded in the reserve tank, if not reserved slots, can also be used for high strength steel nails, and its use of self-adhesive, directly pasted on the construction joint interface, through the isolation paper uniform compaction.

3) Sealing strip fixed end, tear off isolation paper will be poured concrete under.

4) Seal paste parts can be selected in the opening laterally mounted.

5) For sealing strip is firmly fixed, horizontal seam at intervals of 1m high strength steel for nailing, vertical seam at intervals of 0.5m high strength steel for nailing.

Several kinds of usage

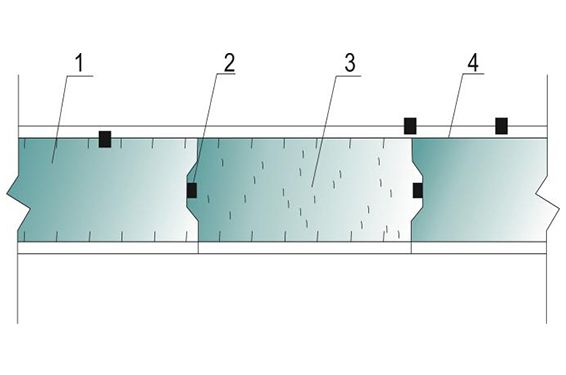

1) After pouring waterproof structure

● Earlier pouring concrete

● Water swelling strips

● Later shrinkage-compensating concrete

● Structure of the main reinforcement

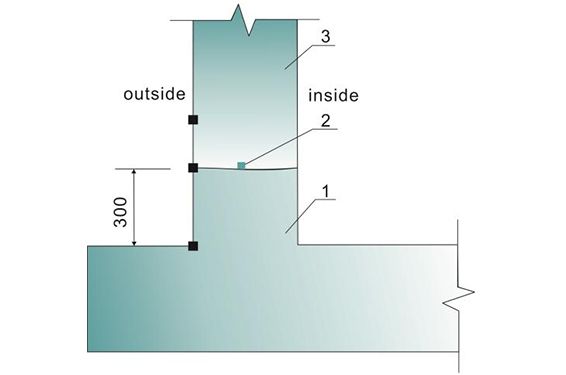

2) Construction joints of waterproof structure

● Earlier pouring concrete

● Water swelling strips

● Later shrinkage-compensating

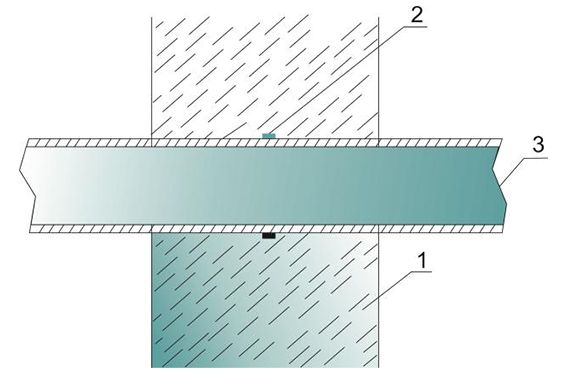

3) Wearing waterproof wall steel structure

● Concrete wallboard

● Water swelling strip

● Steel pipe

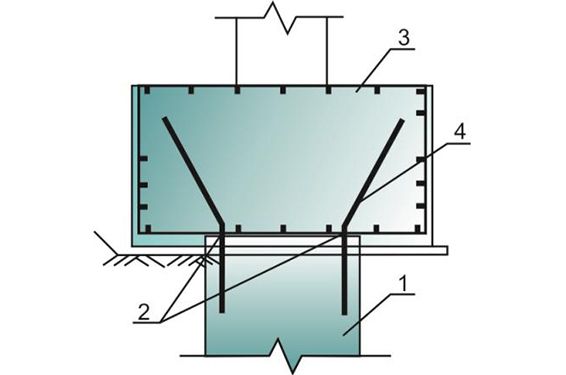

● The pile head waterproof structure

● Concrete pile

● Water swelling strip

● Concrete bearing platform

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.