Pvc waterstop also known as PVC water bar, is designed to provided an overall sealing system for the movable joints and construction joints in cast-in-place concrete. such joints usually exist in the following types of buildings.

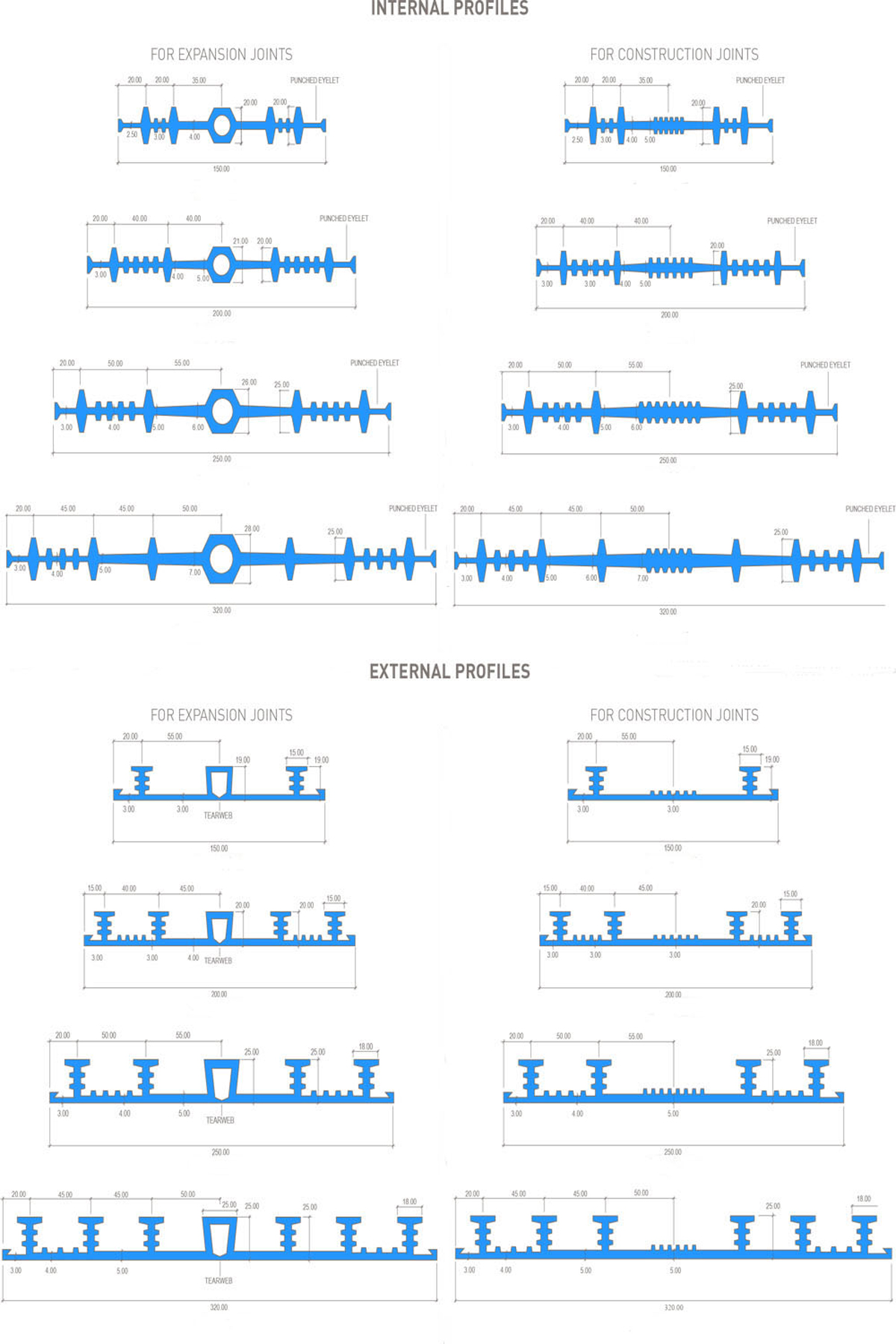

Polyvinyl chloride (PVC) waterstops are used as impervious membranes, embedded in concrete, through and along joints, in environmental engineered concrete structures. Flexible PVC waterstop for sealing construction and expansion joints in concrete structures. Yongxi provides PVC water bar and waterstops in different materials, sizes and types, depending on their purpose.

Features of PVC Water Bar

Easy field welding

Suitable for high water pressure

High-quality composite PVC for long-term durability and integrity

Various profiles and sizes to meet all construction requirements

Product Detail

Water storage building:

Reservoirs, water towers and sewage towers

Dams, culverts, canals and spillways

The swimming pool

The berm area around the storage tank

Waterproof building:

Basement and underground parking

Tunnels and underpasses

Abutment and retaining walls

Roof deck and podium area

Functional principle of pvc waterstop:

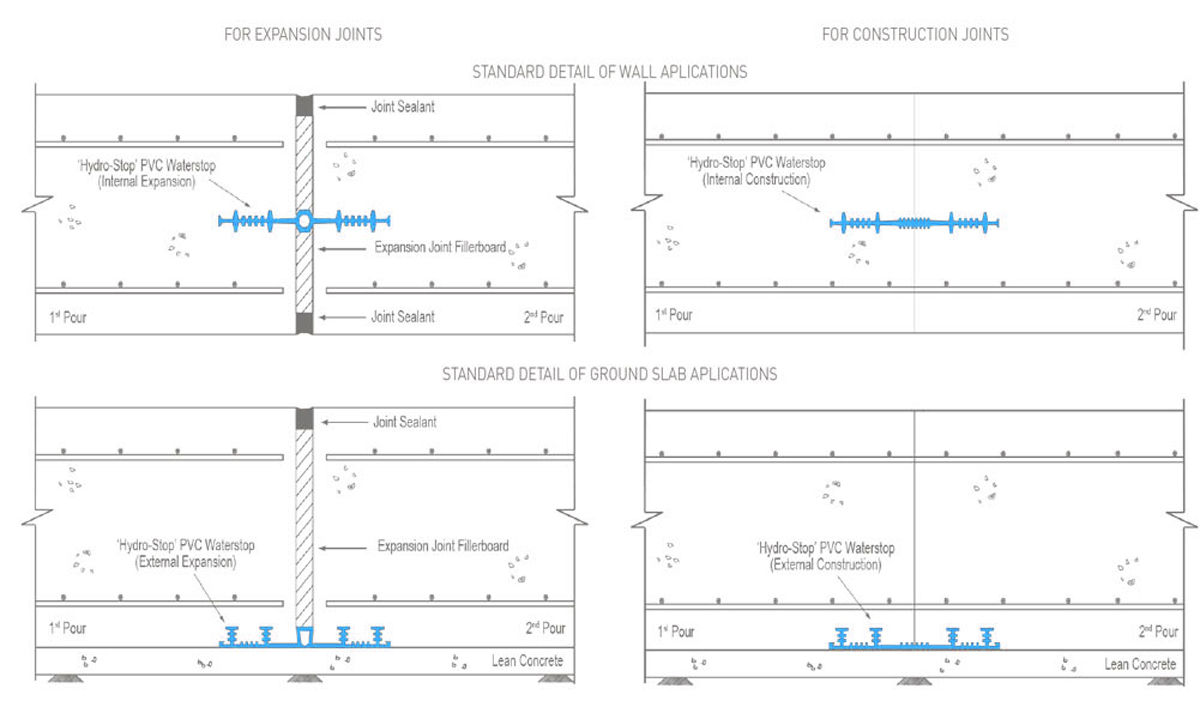

1. Dumbbell shaped waterstop is poured through concrete and embedded in the edge of adjacent concrete, and the concrete slab acts as a baffle. When the joint is opened due to dry shrinkage or other displacement, the edge bulge on the section of the waterstop will play an anchoring role. Therefore, the transverse tension of the waterstop will produce a sealing effect on the inner surface of the edge bulge.

2. After the section of the waterstop becomes complex, its surface area will be greatly increased, which will have a greater organizational effect on the water leakage of the waterstop section, and the complex path formed on the section will make it difficult for water to pass through. If you are looking for wholesale PVC water bar, welcomre to contact us!

| No. | Item | Parameter | ||

| 1 | Hardness Shore A | ≥65 | ||

| 2 | Tensile Strength≥ | 10Mpa | ||

| 3 | Elongation at break ≥ | 300% | ||

| 4 | Tearing strength kn/m ≥ | 25 | ||

| 5 | Brittleness strength kn/m ≤ | -30 | ||

| 6 | Hot air aging | 70℃*72h% | Hardness Shore A ≤ | +8 |

| Tensile Strength N/mm² ≥ | 10 | |||

| Elongation at break ≥ | 240 | |||

Design criteria:

The selection of width and thickness of PVC waterstop largely depends on the thickness of concrete, the location of reinforcement, aggregate specification and the complexity of pouring. Generally, for 250mm concrete, a slightly narrow waterstop with a width close to the wall thickness is suitable.

Precautions for installation of waterstop

The installation method of waterstop must ensure that the waterstop can be firmly positioned in the correct position during concrete pouring. The concrete around the waterstop must be fully tamped to ensure that there are no cavities or porous areas. At the position with reinforcement, sufficient spacing must be kept from the reinforcement to allow sufficient vibration.

The copper ship wire ring used to fix the water stop is located outside the edge protrusion to ensure that no water seepage path is formed around the water stop.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.