Building seismic isolation technique uses the isolation layer to develop the function of “isolation”, and separates the superstructures and substructures. As the hardness of the isolation layer is small, it will effectively reduce 70%-90% earthquake response, which equals to reducing 1-2 degree of seismic intensity and cut 5-20% engineering costs. Seismic isolators for buildings are widely used in lifeline engineering, major construction projects and ordinary housing construction. Besides the new established engineering, building seismic insulator is also widely applied in improvement and reinforcement of the old buildings regarding as a great leap in seismic isolation technique.

Product Detail

The building isolation lead rubber bearing is composed of multi-layer rubber and multi-layer steel plate . Corresponding to the requirements of different buildings and bridges, the lead rubber bearing can be designed in different laminated structures, manufacturing processes and formula design to meet the required stiffness, deformation, damping and durability requirements, and ensure that it has a service life of no less than 80 years.

At the same time, the structural design of building isolation rubber bearings used in the project shall meet the requirements of relevant national and international codes, regulations and standards.

Lead rubber bearing construction

1. Lead plug: dissipate energy and reduce displacement of rubber bearing.

2. Rubber cover: protect the reinforced steel plate and rubber layer.

3. Top and bottom plates: the transfer load and restraint deformation of the lead core.

4. Reinforcing steel plate: increase the vertical stiffness and restraint deformation of the lead core.

5. Internal rubber layer: supports the weight of the structure, adapts to rotation and displacement and restores the mobile bearing to its original position.

Structure Lead rubber bearing building seismic isolation

The building isolation lead rubber bearing is composed of multi-layer rubber and multi-layer steel plate . Corresponding to the requirements of different buildings and bridges, the isolation lead rubber bearing can be designed in different laminated structures, manufacturing processes and formula design to meet the required stiffness, deformation, damping and durability requirements, and ensure that it has a service life of no less than 80 years. At the same time, the structural design of building isolation rubber bearings used in the project shall meet the requirements of relevant national and international codes, regulations and standards.

Working performance and principle

The structure of multi-layer rubber and reinforced steel plate bears the weight and horizontal displacement of the building. When the multi-layer rubber is sheared and deformed, the lead core absorbs energy by plastic deformation. After the earthquake, the lead core automatically restores the building to its original position through the dynamic recovery and recrystallization process and the shear tension of rubber.

TESTING

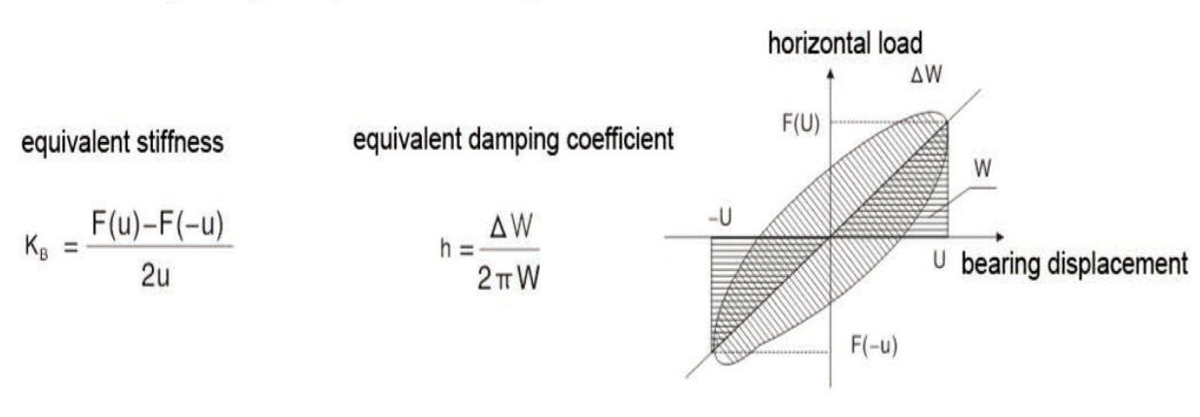

The test process can be followed to standard testing requests or specific experimental methods according to different project designing requests.

Variation of theoretical curve under different displacements,The test process can be followed to standard testing requests or specific experimental methods according to different project designing requests

Lead rubber bearing construction features

1. Stable vertical stiffness, excellent vertical bearing capacity and damping performance.

2. High purity lead. The lead core in the building seismic isolator we use is of high purity and does not contain any impurities.

3. High durability and elasticity of rubber parts - will not suffer any damage during and after earthquakes.

4. Adjustable lead area. Different damping ratios can be adapted by adjusting the wire diameter and cross-sectional area.

5. Corrosion resistance. The steel plate is completely embedded in the rubber and sealed.

6. Anti-aging. A rubber layer covers the surface of the rubber bearing surface to protect the internal rubber.

7. Long life. 60-80 years of service life, durable.

8. Easy to install and replace, reducing maintenance cost.

As a professional lead rubber bearing manufacturer and seismic isolator supplier, high performance lead rubber bearing base isolation, seismic isolations, railway pot bearings and highway bridge bearings are provided by Yongxi with exellent product quality and aftersales service. Please feel free to contact us for the latest lead rubber bearing price.

There are five basic conditions to the building isolation

It can support the weight of the upper part of the building, and the vertical deformation is small;

The stiffness of the isolation layer is required to be very small, in order to effectively isolate the transmission of earthquake motion;

Once an earthquake occurs, the building vibration is required to automatically return to the original state;

The isolation layer should be able to absorb the energy input by the earthquake, reducing the transmission of energy to the upper building;

There should be enough deformation space to allow the building to vibrate freely.

Applicable building types of building seismic isolator

The seismic performance of buildings is significantly improved by using isolation technology, so it can be used in the following types of buildings

Primary and secondary school buildings, hospital buildings.

Communication, fire fighting, electric power and other important buildings

Important government organs, disaster prevention command center, earthquake emergency shelter building;

Bank, insurance and other data information center

Buildings where valuables and dangerous goods are placed

Library and memorial building

Large commercial complex

Residential building

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.