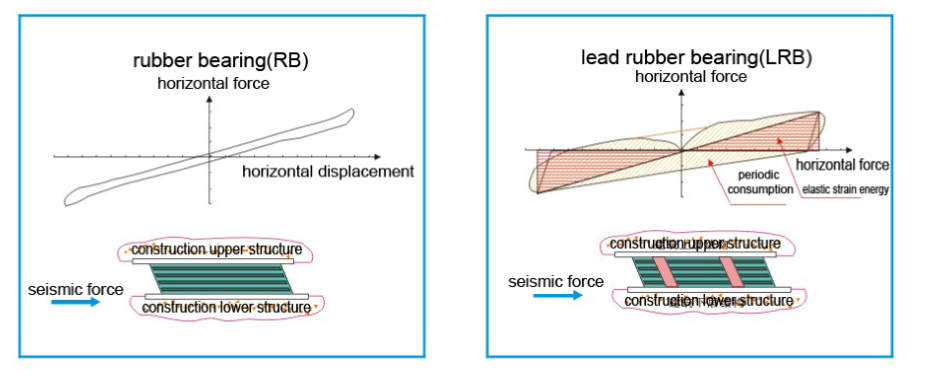

Lead rubber bearing is also called lead core rubber bearing, LRB isolator, its structure is similar to high damping rubber bearing. It is an important part of the isolation bearing. Seismic resistance bridge bearing consists of laminated rubber bearings and a lead core. The lead core can not only withstand heavy loads and horizontal forces, but also absorb energy through hysteresis damped plastic deformation. The lead rubber bearing for bridge is different from the lead rubber bearing used in buildings. It must also have the ability to absorb the small vibration up and down the bridge and the ability to support the rotation of the bridge.

The bridge is an open-air structure. The anti seismic rubber bearing from Yongxi adopted shall be stable in material and function for a long time. Therefore, the LRB isolator shall have good static characteristics, including durability, temperature stability and vertical bearing capacity. The elastomeric seismic isolators bearing used on the bridge will be subjected to the reciprocating action of seismic force in case of earthquake. Therefore, the seismic isolation bearing should also have good dynamic performance, large deformation capacity and parameter stability under the repeated load caused by earthquake.

Product Detail

Advantages of isolation rubber bearing over ordinary plate bearing

The damping ratio of lead rubber bearing can generally be more than 15%, and that of ordinary plate bearing is less than 5%, Lead rubber bearings can delay the structural period of the bridge and greatly reduce the acceleration of the bridge superstructure. Because the lead core isolation bearing significantly improves the stress of the structure during the earthquake, the lead rubber bearing can be set in areas above 8 degrees, and the overall cost of the bridge can also be reduced.

As a professional lead rubber bearing supplier, we can provide Seismic Isolations, railway bridge bearing and highway bridge bearing with custom service. Welcome to contact us for detailed information!

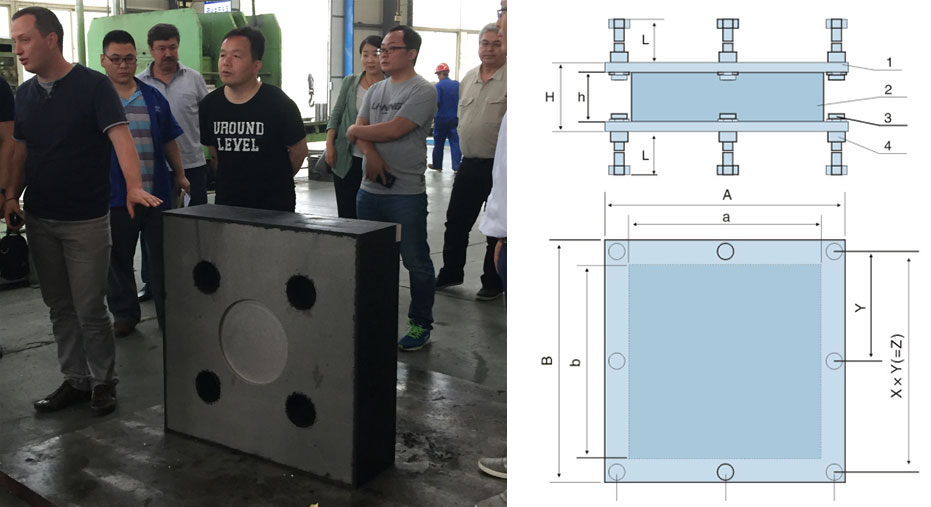

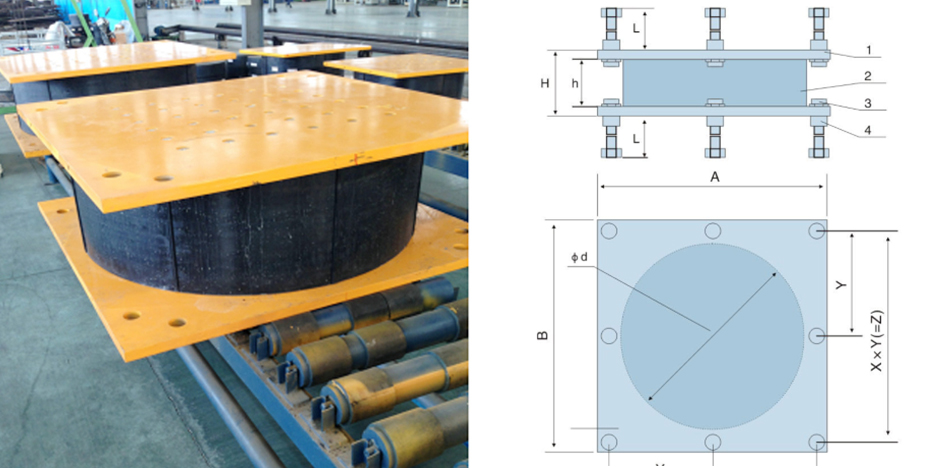

Schematic diagram of square isolation of lead rubber bearing

Our standard dimension range can reach to D1470mm

Features of seismic resistance bridge bearing

Corrosion resistance. The steel plate is completely embedded in the rubber and sealed.

Long life. 60-80 years of service life, durable.

Easy to maintain. Easy to install and replace, reducing maintenance costs.

Anti-aging. A rubber layer covers the surface of the bearing surface to protect the internal rubber.

High purity lead. The lead core in the lead rubber bearings we use is of high purity and does not contain any impurities.

Adjustable lead core area. Different damping ratios can be adapted by adjusting the wire diameter and cross-sectional area.

Practical features. The lead rubber bearings for bridge not only control the amount of displacement, but also prevent the bridge from collapsing.

Strong recovery ability. When subjected to a large displacement, the lead rubber bearing with high ductility will not produce residual deformation and can recover by itself.

Excellent shock resistance. Lead cores in bridge bearings have high levels of damping up to 30%, and plastic deformation occurs when the bearings move laterally in an earthquake.

Material of lead rubber bearing

The lead used for lead rubber bearing must be high purity lead without any impurities;

Physical properties of rubber materials

| NO. | TEST ITEM | TECHNOLOGY REQUIREMENT | UNIT | |

| 1 | HARDNESS (SHORE A) | 60±5 | HD | |

| 2 | TENSILE STRENGTH | ≥18 | MPA | |

| 3 | ELONGATION AT BREAK | ≥550 | % | |

| 4 | COMPRESSION SET | 70℃×24H | ≤30 | % |

| 5 | BRITTLENESS TEMPERATURE | ≤-50 | ℃ | |

| 8 | OZONE AGING(50PPHM, 20%ELONGATION, 40℃×48H) | NO CREAK | --- | |

| 9 | AIR AGING | HARDNESS CHANGE (SHORE A) | ≤+6 | HD |

| TENSILE STRENGTH CHANG RATE | ≤12 | % | ||

| ELONGATION AT BREAK CHANG RATE | ≤20 | % | ||

Tests

According to the European standard for isolation bearings, detailed performance inspection requirements are put forward for lead rubber bearings. The European standard prefers to inspect the isolation performance of isolation bearings under reciprocating load. For different projects, due to the design requirements, there can be specific inspection operation methods. Our manufacturer should inspect according to the standards and specific requirements for different projects.

(Testing laboratory )

Production and Packaging

The rubber and reinforced steel plate are vulcanized together to form a laminated rubber bearing. During this process, the lead core position should be reserved in advance.

The lead core is pressed into the reserved position and vulcanized together.

Vulcanized upper and lower sealing steel plates.

Connect the upper and lower connecting steel plates with anchor bolts.

Cover the lead rubber bearing with plastic film.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.