Home < Products < Railway Simply Supported Beam Bridge Bearings < Passenger-dedicated Railway Line Pot bearing (KTPD)

The railway bridge pot bearing, with an elastic bearing pad installed in the steel plate, is used to pass the vertical or horizontal load from the upper structure to the pier, which allows the most widely used type to rotate on any shaft. The friction coefficient between stainless steel plates and a layer of PTFE can adapt to the horizontal displacement of the upper structure.

The components of pot bearings for bridges are high loads and thin bearing, which are used for isolation and supporting heavy structures. Suitable for complex structures that are curved or tilted and the rotation direction changes or cannot be accurately determined.

Railway pot bearing elements:

● Elastic pad-allow higher work pressure and smaller size.

● Stainless steel plates and polytetrafluoroethylene -reduce friction resistance and horizontal force.

● Steel piston and internal bronze dens to seal -protection elastic pads are not squeezed.

● Steel -top -can adapt to the vertical or horizontal sliding movement of the upper structure.

Railway bridge pot bearing features:

● The low friction coefficient is between 1% and 3%.

● Has a high load capacity of more than 50,000 kn.

● The PTFE layer has excellent anti -fatigue, impact and anti -aging performance.

● Installation is simple and fast, easy to maintain and replace wear and damage parts.

● All metal components are protected by galvanized and epoxy resin to avoid corrosion.

● The elastic pads are wrapped in the steel pot, which improves the shear strength of the elastic pad to the greatest extent.

Product Detail

Technical performance:

1. There are 6 levels of bearing capacity of simply supported T-beam: 1000KN, 1500KN, 2000KN, 2500KN, 3000KN, 3500KN.

There are 9 levels of the vertical bearing capacity of simply supported box girder: 2500KN, 3000KN, 3500KN, 4000KN, 4500KN, 5000KN, 5500KN, 6000KN,

7000KN.

There are 22 levels of vertical bearing capacity of continuous beam: 4000KN- 45000KN.

2. The design horizontal force of the fixed bearing, the longitudinal movable bearing in the transverse bridge direction, and the transverse movable bearing along the bridge direction is 15%, 20%, 30% of the vertical design bearing capacity of the bearings:

● 15%-In the area with a peak ground acceleration is Ag ≤ 0.1g

● 20%-In the area with a peak ground acceleration is 0.1g<Ag≤0.15g

● 30%-In the area with a peak ground acceleration is 0.15g<Ag≤0.2g

● 40%-In the area with a peak ground acceleration is 0.2g<Ag≤0.3g

● The design horizontal force of the bidirectional movable bearing in each direction, the longitudinal movable bearing along the bridge direction and the horizontal movable bearing in the transverse direction is 5% of the vertical design bearing capacity of the bearing.

When the design unit uses these bearings, if the actual horizontal force is found to be large, the bearing with the corresponding horizontal force can be selected. For example, the0.15g, 0.2g, 0.3g bearing in the original Ag≤0.1g area can be selected according to the actual horizontal force .

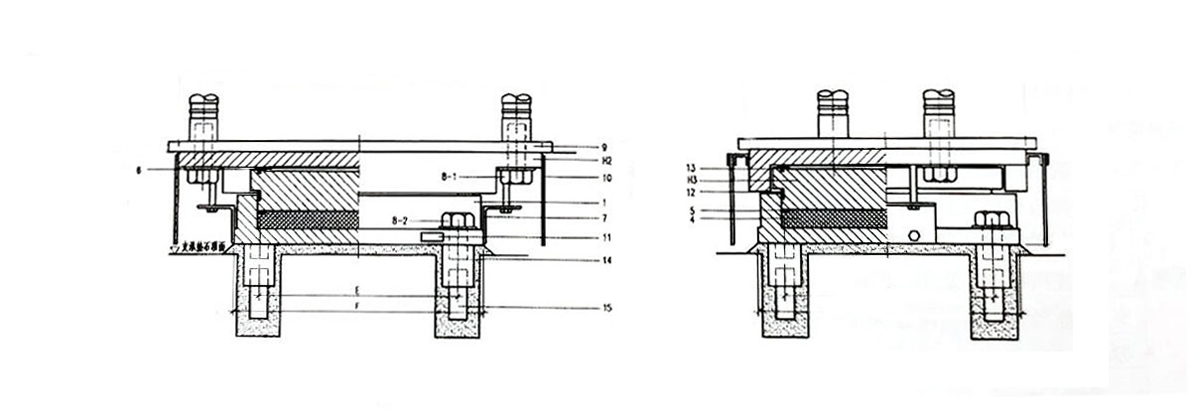

3. Design displacement of bearing

Bidirectional movable bearing and ZX longitudinal movable bearing along the bridge direction.

Simply supported beam:

● Vertical Bearing Capacity: 1000KN~ 2000KN, the design displacement: ± 30mm.

● Vertical Bearing Capacity: 2500KN~3000KN, the design displacement: ± 50mm.

● Vertical Bearing Capacity: 3500KN~7000KN, the design displacement: ± 60mm.

Continuous beam:

● Vertical bearing capacity 4000KN~ 45000KN is ± 100mm

When the displacement required by the user exceeds ± 100 mm, the size of the bearing plate on the pot PTFE bearings for bridges can be changed according to the actual displacement. See the design description in the general assembly drawing of various bearings for the change method.

The design displacement of the bidirectional movable bearing and transverse movable bearing in the transverse direction is ±10m

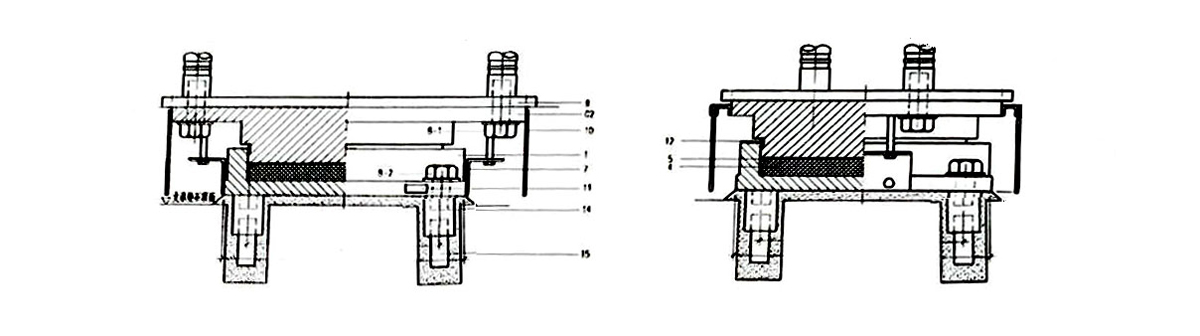

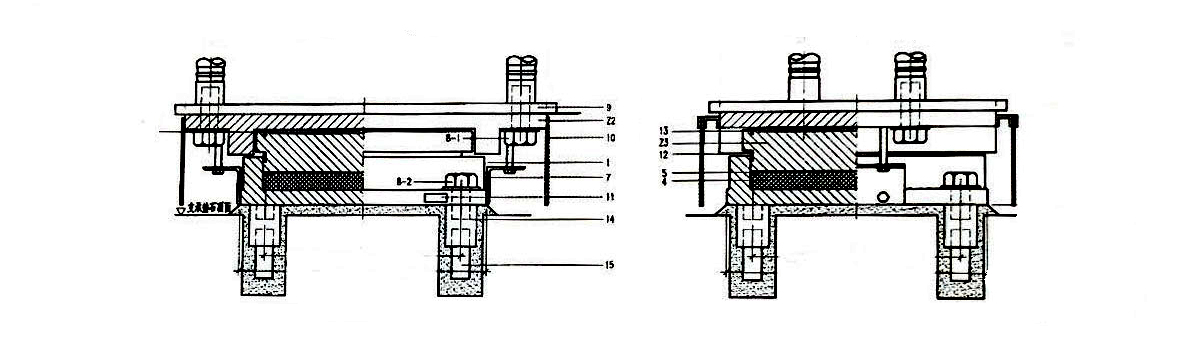

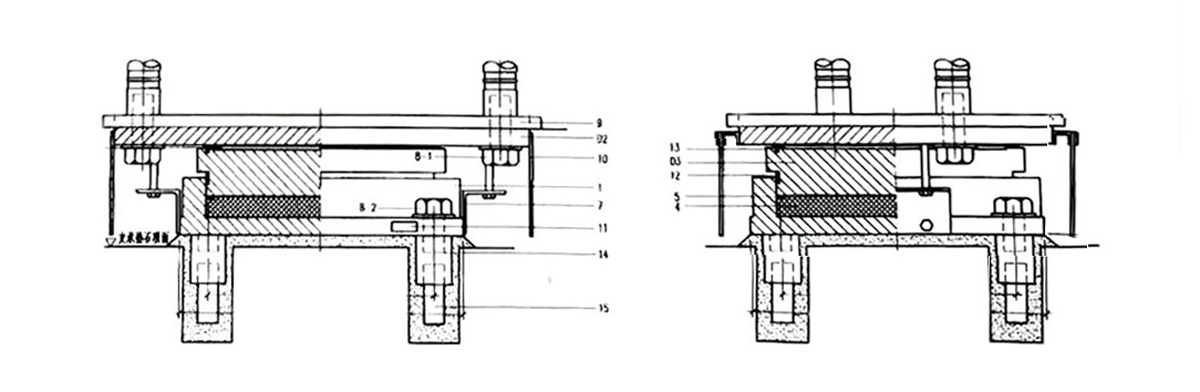

4. Structure

FIXED-KTPD

Longitudinal-KTPD

Multidirectional-KTPD

Transverse-KTPD

5. Design friction coefficient of movable bearing:

● Normal temperature type: μ≤0.03,

● Cold-resistant type: μ≤0.05

6. Applicable range of temperature:

● Normal temperature type -25℃~+60℃ adopts neoprene or natural rubber;

● Cold-resistant type -40℃~+60℃ adopts EPDM or natural rubber.

7. Bearing design angle: 0.02rad.

8. When the slope of the project line is 0-20 ‰, The top surface wedge angle of upper support plate is changed to meet the slope requirements of the beam.

● When the slope of the project line is 0‰<i<4‰, no wedge angle is set of the upper support plate.

● When the project slope is 4‰<i<12‰, the slope of top surface of upper bridge bearing plate is preset to be 8 ‰ slope.

● When the slope is 12‰<i<20‰, The top surface wedge angle of upper support plate is preset to be 16 ‰.

When the slope of the project is greater than 20 ‰, Instead of setting wedge angle on the top surface of upper support plate, adjust the slope at the bottom of the beam.

There is no slope on the top of the bearing plate on the cast-in-place simply supported beam bearing, and the slope of the project is adjusted by the beam bottom.

Besides the railway pot bearing, Yongxi also provides high performance pot bearing and spherical bearing for railway and highway bridge. For any questions or special requirements, please feel free to contact us!

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.