Home < Products < Railway Simply Supported Beam Bridge Bearings < Hyperboloid steel structural bearing (SHSS)

Product Detail

Technical performance:

1. There are four levels of vertical bearing capacity 1500KN, 2000KN, 2500KN, 3000KN.

2. The design angle of the bearing:

Longitudinal direction: 0.02rad.

Transverse direction: 0.06rad.

3. Design Horizontal main force:

The design horizontal forces of the fixed bearing, the transverse direction of the longitudinal movable bearing and the along bridge direction of transverse movable bearing are 15%, 20%, 30% and 40% of the vertical design bearing capacity.

Detailed usage as bellow:

● 15%-In the area with a peak ground acceleration is Ag ≤ 0.1g

● 20%-In the area with a peak ground acceleration is 0.1g<Ag≤0.15g

● 30%-In the area with a peak ground acceleration is 0.15g<Ag≤0.2g

● 40%-In the area with a peak ground acceleration is 0.2g<Ag≤0.3g

The design horizontal force of the two way movable bearing in all directions, along the bridge direction of the longitudinal movable bearing and in the transverse direction of the transverse movable bearing is 5% of the vertical design bearing capacity.

4. Structure and displacements

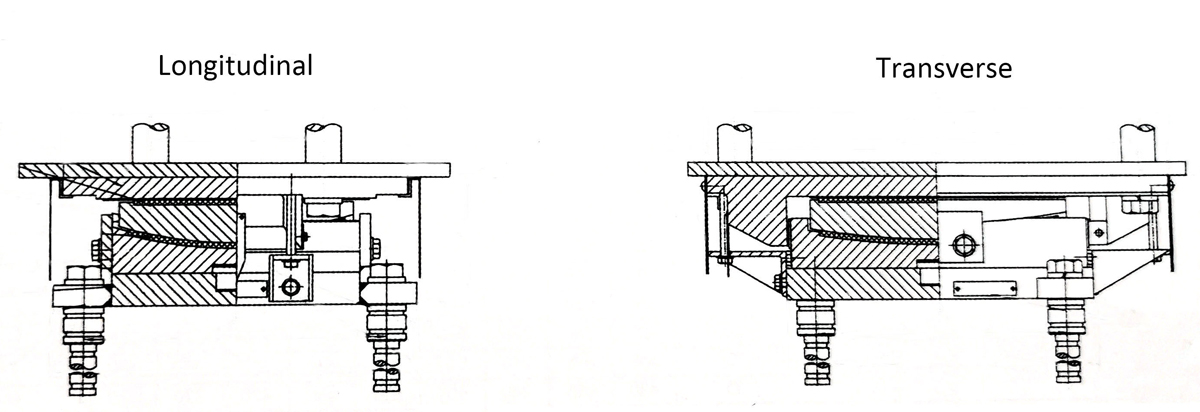

① longitudinal movable bearing (LMB): The along bridge direction design displacement is ±30mm

Longitudinal-SHSS

| SHSS-LMB | PGA | Reaction force(KN) | Longitudinal displacement(mm) |

| SHSS-1500 LMB | a≤0.1g | 1500 | ±30 |

| SHSS-2000 LMB | 2000 | ±30 | |

| SHSS-2500 LMB | 2500 | ±30 | |

| SHSS-3000 LMB | 3000 | ±30 | |

| SHSS-1500 LMB | 0.1g<a≤0.1 5g | 1500 | ±30 |

| SHSS-2000 LMB | 2000 | ±30 | |

| SHSS-2500 LMB | 2500 | ±30 | |

| SHSS-3000 LMB | 3000 | ±30 | |

| SHSS-1500 LMB | 0.15g<a≤0.2g | 1500 | ±30 |

| SHSS-2000 LMB | 2000 | ±30 | |

| SHSS-2500 LMB | 2500 | ±30 | |

| SHSS-3000 LMB | 3000 | ±30 | |

| SHSS-1500 LMB | 0.2g<a≤0.3g | 1500 | ±30 |

| SHSS-2000 LMB | 2000 | ±30 | |

| SHSS-2500 LMB | 2500 | ±30 | |

| SHSS-3000 LMB | 3000 | ±30 |

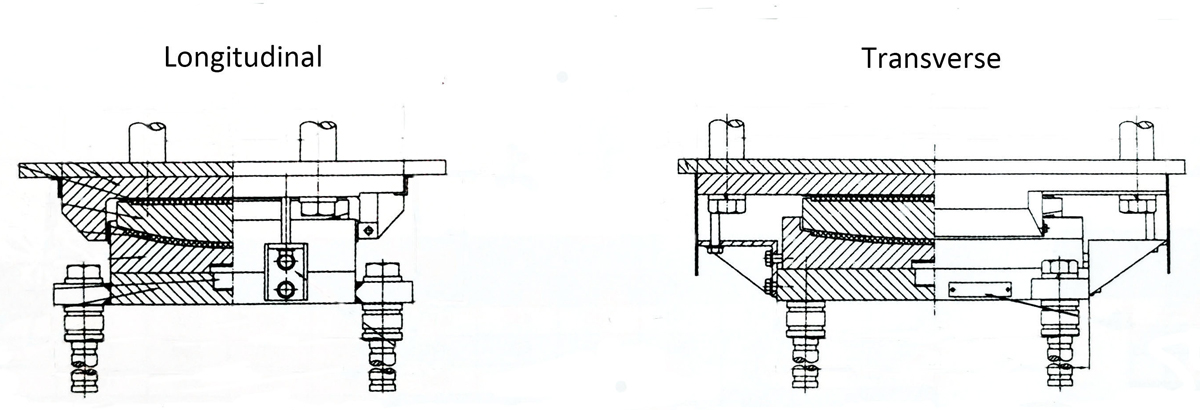

② Transverse movable bearing (TMB): Transverse displacement of transverse movable bearing is ±40mm

Transverse-SHSS

| SHSS-TMB | PGA | Reaction force(KN) | Longitudinal displacement(mm) |

| SHSS-1500 TMB | a≤0.1g | 1500 | ±10 |

| SHSS-2000 TMB | 2000 | ±10 | |

| SHSS-2500 TMB | 2500 | ±10 | |

| SHSS-3000 TMB | 3000 | ±10 | |

| SHSS-1500 TMB | 0.1g<a≤0.1 5g | 1500 | ±10 |

| SHSS-2000 TMB | 2000 | ±10 | |

| SHSS-2500 TMB | 2500 | ±10 | |

| SHSS-3000 TMB | 3000 | ±10 | |

| SHSS-1500 TMB | 0.15g<a≤0.2g | 1500 | ±10 |

| SHSS-2000 TMB | 2000 | ±10 | |

| SHSS-2500 TMB | 2500 | ±10 | |

| SHSS-3000 TMB | 3000 | ±10 | |

| SHSS-1500 TMB | 0.2g<a≤0.3g | 1500 | ±10 |

| SHSS-2000 TMB | 2000 | ±10 | |

| SHSS-2500 TMB | 2500 | ±10 | |

| SHSS-3000 TMB | 3000 | ±10 |

③ Transverse displacement of two-direction movable bearing is ±40mm

| SHSS-TDM | PGA | Reaction force(KN) | Longitudinal displacement(mm) |

| SHSS-1500 TDM | a≤0.1g | 1500 | ±30 |

| SHSS-2000 TDM | 2000 | ±30 | |

| SHSS-2500 TDM | 2500 | ±30 | |

| SHSS-3000 TDM | 3000 | ±30 | |

| SHSS-1500 TDM | 0.1g<a≤0.1 5g | 1500 | ±30 |

| SHSS-2000 TDM | 2000 | ±30 | |

| SHSS-2500 TDM | 2500 | ±30 | |

| SHSS-3000 TDM | 3000 | ±30 | |

| SHSS-1500 TDM | 0.15g<a≤0.2g | 1500 | ±30 |

| SHSS-2000 TDM | 2000 | ±30 | |

| SHSS-2500 TDM | 2500 | ±30 | |

| SHSS-3000 TDM | 3000 | ±30 | |

| SHSS-1500 TDM | 0.2g<a≤0.3g | 1500 | ±30 |

| SHSS-2000 TDM | 2000 | ±30 | |

| SHSS-2500 TDM | 2500 | ±30 | |

| SHSS-3000 TDM | 3000 | ±30 |

④ Structure Fix types Hyperboloid steel structural bearing

5. Bearing design friction coefficient: The friction coefficient of the movable bearing is taken under the condition of silicone grease lubrication.

● Normal temperature type: μ≤0.03,

● Cold-resistant type: μ≤0.05

6. Applicable temperature range of bearing:

● Normal temperature type: -25℃~+60℃;

● Cold-resistant type: -40℃~+60℃.

7. When the slope of the project line is 0-20 ‰, The top surface wedge angle of upper support plate is changed to meet the slope requirements of the beam.

● When the slope of the project line is 0‰<i<4‰, no wedge angle is set of the upper support plate.

● When the project slope is 4‰<i<12‰, the slope of top surface of upper bridge bearing plate is preset to be 8 ‰ slope.

● When the slope is 12‰<i<20‰, The top surface wedge angle of upper support plate is preset to be 16 ‰ slope.

When the slope of the project is greater than 20 ‰, Instead of setting wedge angle on the top surface of upper support plate, adjust the slope at the bottom of the beam.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.