Product Detail

Technical performance

Vertical bearing capacity: 4000KN -45000KN.

When the vertical bearing capacity is more than 45000KN, it can be designed separately.

1. Design angle of bearing: 0.02rad

2. The design horizontal force of the fixed bearing, the longitudinal movable bearing in the transverse bridge direction, and the transverse movable bearing along the bridge direction is 15%,30% of the vertical design bearing capacity of the bearings:

● 15%-In the area with acceleration of peak ground motion is Ag ≤ 0.1g

● 30%-In the area with acceleration of peak ground motion is 0.1g<Ag≤0.2g

When selecting bearings, the corresponding bearings should be selected according to the actual design horizontal force of the bridge.

The design horizontal force of the two way movable bearing in each direction, the longitudinal movable bearing along the bridge direction and the horizontal movable bearing in the transverse direction is 5% of the vertical design bearing capacity of the bearing.

When the peak acceleration is greater than 0.2g, it can be designed separately

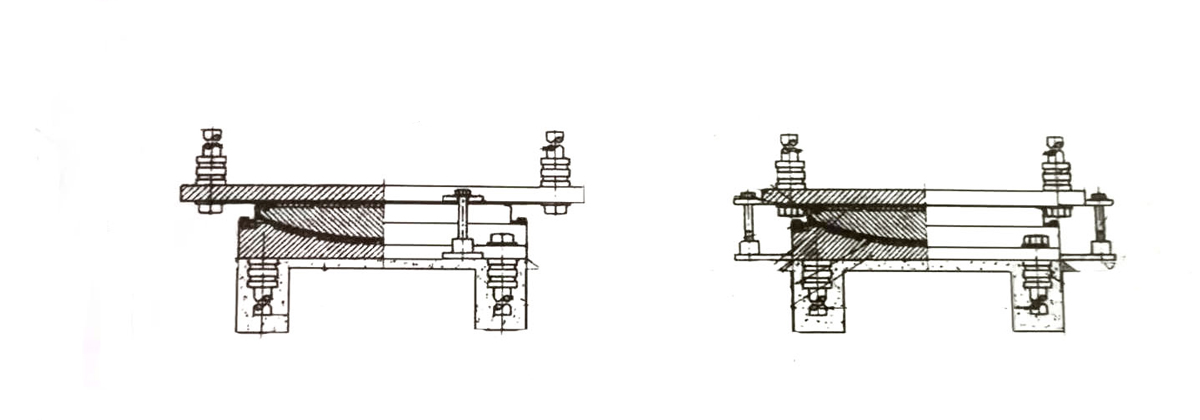

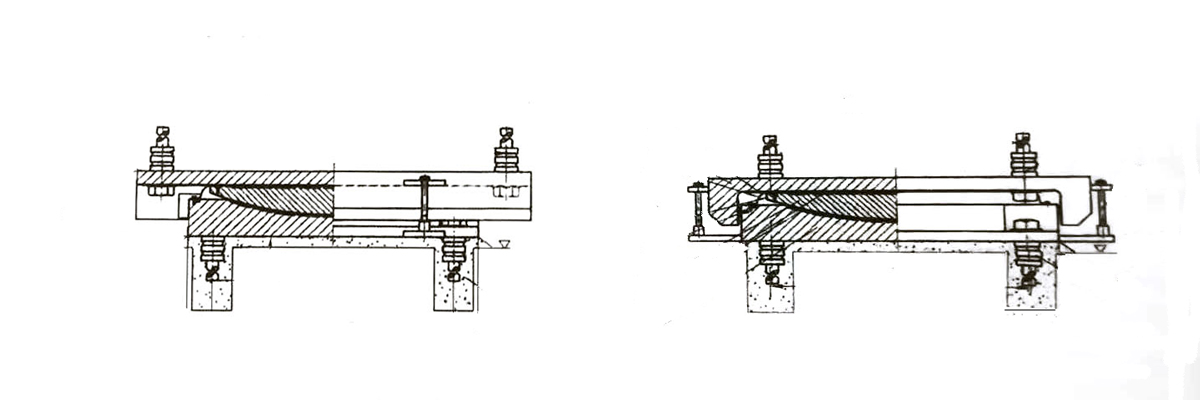

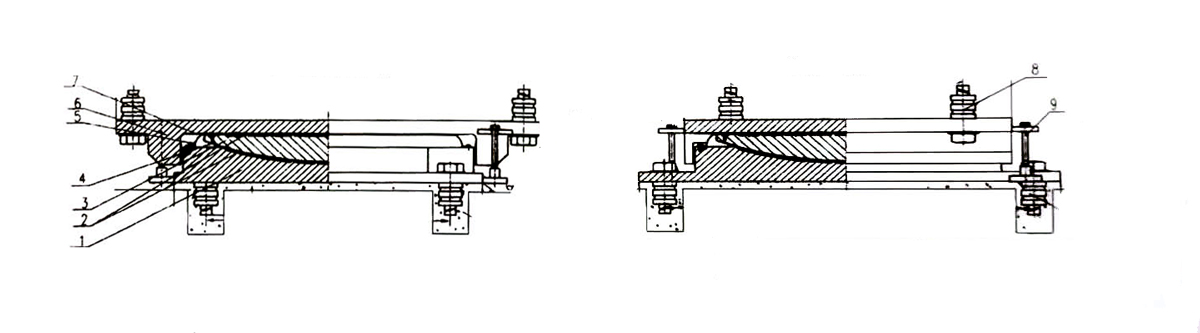

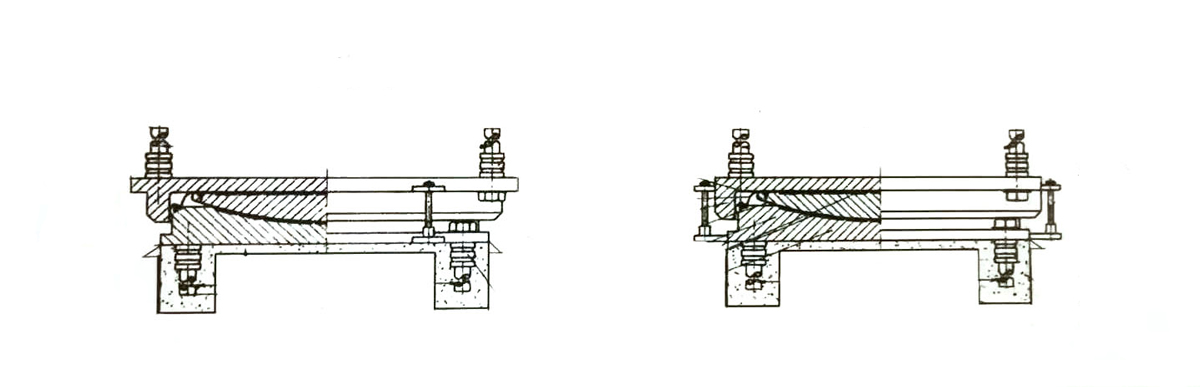

3. Displacements and structure

The maximum displacement along the bridge direction of multi-directional movable bearing and longitudinal movable bearing are ±100mm, ±150mm

Design displacement along the bridge direction of multi directional movable bearing and transverse movable bearing are ±10mm.

The design displacement range of this series of bearings is as follows: ±50mm, ±100mm, ±150mm, ±200mm, ±250mm.

When the required displacement is greater than the above value, it can be designed separately.

5. Bearing design friction coefficient: the value of the design friction coefficient of the movable bearing under the condition of silicone grease lubrication:

● Normal Temperature(-25℃~60℃); μ≤0.03.

● Low temperature(-40℃~-25℃): μ≤0.05.

6. Applicable range of temperature: 40℃~+60℃.

7. Reserved height adjustment of bearing: the reserved height adjustment of the bearing in the bolt length of the upper bearing plate shall not be less than 20 mm.

8. There is no slope on the top surface of the base plate on the bearing, the slope of the bridge is adjusted by the concrete at the bottom of the beam, and the bearing is placed horizontally.

9. When the bearing is used in coastal atmospheric environment or heavily polluted areas, the material selection and surface coating of the bearing shall meet the corresponding atmospheric environment service life requirements

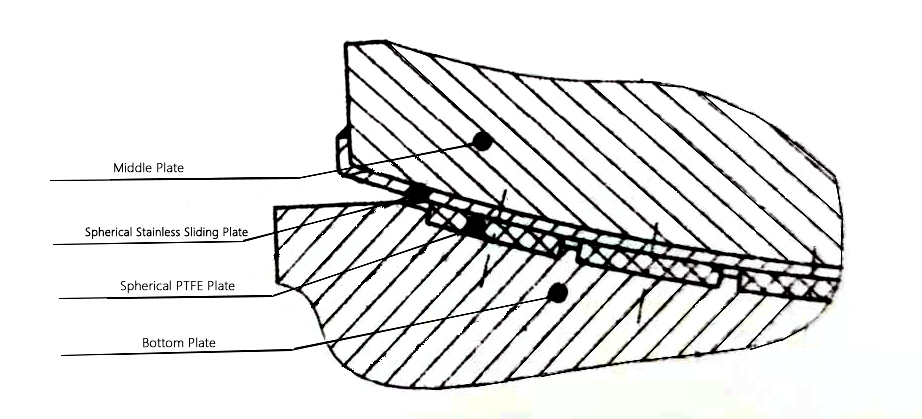

10. In order to enhance the durability of this series of bearings, the following measures are adopted in the structural design of bearings

(1) The lower surface of the upper base plate is covered with stainless steel sliding plate

(2) The sliding plate is fixed by block mosaic structure

(3) The dust-proof seal on the friction surface of the support shall adopt the distributed full sealing device. The dust-proof sealing device shall be made of non combustible and non-aging corrosion-resistant materials

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.