key words: PTFE sliding bearing pad,rubber bearing pad, rubber pad, ptfe sliding pad

1. PTFE Sliding Rubber Bearing Pad Summary

The sliding rubber bearing pads is one kind of new type construction material, it is mainly used on building loading structure , and it can dispersed load effectively, to protect the building and bridge construction, make them more stablely and more safety. Besides, the PTFE sliding pad has good capacity of compressive, tensile, and wear-resistant properties, and widely used on bridge and building construction, and it is also used on factory equipment for high loading and good sliding properties.

2. The Components Of Structure Of The PTFE Sliding Pad

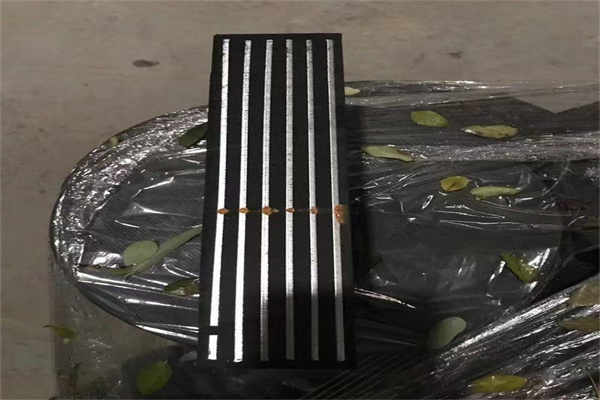

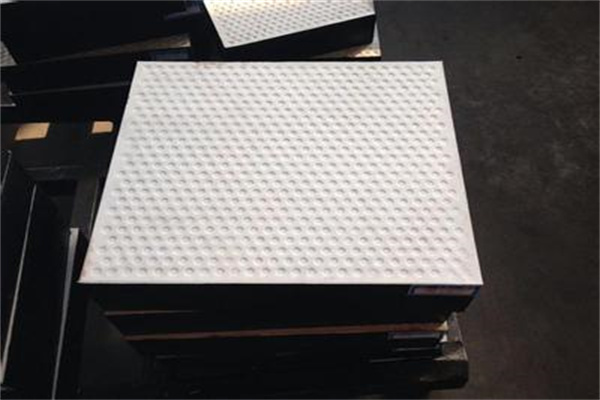

The ptfe sliding pad is mainly made of stainless steel plate, PTFE pad, and rubber bearing pad, the PTFE Pad is bonded on the rubber pad. Because the friction coefficient of PTFE plate is low after using Lubricating silicone grease between the stainless plate and PTFE plate, so the sliding pad can slid smoothly, because of this function, it can be used in many areas. Stainless steel plates have high tensile strength and corrosion resistance, ensuring the stability of the slidng pad In addition, rubber pads play a role in shock absorption and buffering, reducing the vibration and noise of buildings. Plate rubber bearings can reliably transmit the reaction force of the upper structure to the pier and abutment; Has good elasticity to adapt to the rotation of the beam end; It also has a large shear deformation capacity to meet the horizontal displacement of the upper structure. Tetrafluoroethylene sliding rubber bearings are not only technologically advanced

It has excellent performance, simple structure, low price, no maintenance required, easy replacement of buffering and isolation, and low building height. Therefore, it is popular in the bridge industry and widely used.

3.The Usage Range of PTFE sliding Pad

General highway or railway bridge plate rubber bearings are suitable for bridges with spans less than 30m and small displacements. Different plane shapes are suitable for different bridge span structures, and rectangular bearings are used for orthogonal bridges; Circular bearings are used for curved bridges, skew bridges, and cylindrical pier bridges

PTFE plate rubber bearings are suitable for large-span, multi span continuous, simply supported beam continuous plate and other structures with large displacement bridges. They can also be used as sliding blocks in continuous beam top pushing and T-shaped beam lateral movement. The application of rectangular and circular PTFE plate rubber bearings is not the same as that of rectangular and circular ordinary plate rubber bearings.

4. PTFE Sliding Bearing Pad Price

The price of PTFE sliding pad based on normal rubber bearing pad , and is higher than rubber bearing, because there is price of PTFE plate needed to be added. But good sliding plate is necessary, because the Horizontal bearing capacity and sliding capacity needed to be both considered, so not only rubber bearing pad effects on the quality, but PTFE slidng plate decide the quality and long service life of the sliding bearing pads.

5. How To Produce PTFE Sliding Bearing Pad?

As we know, the rubber bearing pad is vulcannized by vulcanizing machine under high pressure and high temperature, and the PTFE plate is bonded on the rubber pad. But there are two ways to do the productions, one way is the produce the rubber bearing seperately and make a mould to suppressing grease pits of PTFE plate, then bonding the it to rubber bearing, the other production method is to suppressing the grease pit on the same mould of rubber bearing when vulcanizing the product, which means not to make a seperate mould for the ptfe plate, and to make the grease pits together on the mould of rubber bearing,

6. PTFE sliding bearing pad testing.

Regarding the tests of ptfe sliding rubber bearing, except the test of regular items of rugular tests of bridge rubber bearings,such as rubber material tests, vertical loading,shearing test, there are also test of PTFE plate. For the test of ptfe plate, we normally test the items of loading, friction coefficient, Wear resistance coefficient. The PTFE plate should has good wear resistance.