keywords:HDRB,LRB,high damping rubber bearing,lead rubber bearing,seismic isolator

1. Differences in materials of HDRB and LRB

The high damping rubber bearing adopts high damping rubber, fully utilizing the rubber's viscoelasticity and damping characteristics. The equivalent damping ratios of this type of high damping rubber bearing are 12%, 15%, and 17%. The equivalent damping ratio of ultra-high damping rubber bearings can be up above 20%, No need to use additional Viscous damper to work together used, and simplifying the installation process and saving overall installation space. We can tell the good damping rate from the viscoelastic hysteresis curve when making testing, Due to the smooth viscoelastic hysteresis curve of high damping rubber and its strong energy absorption ability during earthquakes, it can not only protect the overall safety of buildings but also safeguard the facilities inside.

The structure of Lead core rubber bearings is embedded in natural rubber bearings, this structure makes the natural rubber acts as a "spring" for elastic deformation and lead core acts as a "viscous" damping effect. Vertically press a lead core with a purity of 99.9% into the middle or center of the plate rubber support, and its function of absorbing and dissipating vibration energy is achieved through the shear deformation of the lead core. Due to the ability to select damping by adjusting the diameter or cross-sectional area of the lead core, the design of theLRB has greater flexibility. The reason for using metallic lead is that lead can crystallize again at room temperature after cold deformation. Under repeated loading, lead rubber bearings can maintain their performance and have good durability. The injection of lead rods also increases the early stiffness of the support, which is beneficial for controlling wind response and resisting micro vibrations of the foundation. This type of rubber bearing has a damping coefficient of over 25% and good damping performance.

2. The structure introducton of high damping rubber bearing and Lead rubber bearing

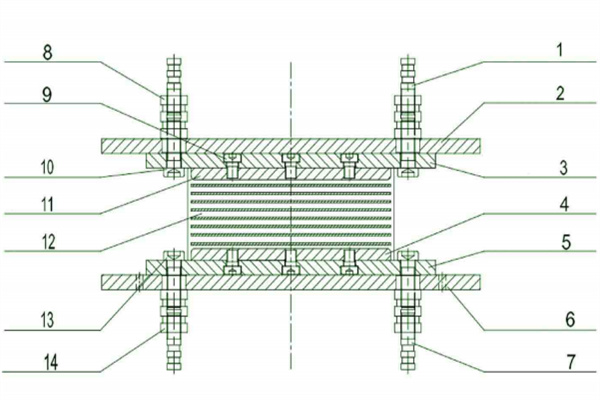

There are two types of high damping rubber bearing, the main difference of the two types is structure, one type connected with bolts, and the other type is vulcanized type.

From the drawing of type 1 , the component are:1. upper sleeve,2. Top embedded steel plate,3.top steel plate, 4.bottom steel plate, 5.bottom rubber bearing steel plate, 6. bottom embeeded steel plate, 7.bottom rock bolt. 8.top rock bolt, 9.connecting bolts, 10, anchor bolt. 11.top steel plate, 12. High damping rubber body. 13 anchor bolt, 14, bottom sleeve.

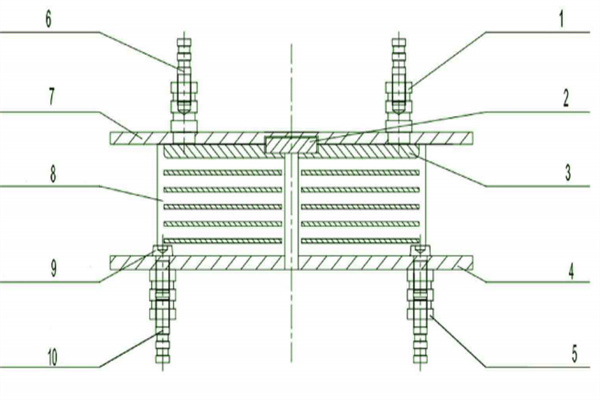

The other type high damping rubber bearing structure is:

1. Upper sleeve, 2. shear reinforce plate, 3.Top steel plate, 4 bottom steel plate,5.bottom plate, 6.upper rock bolt, 7. embedded steel plate. 8. high damping rubber body, 9.anckor bolt, 10, bottom rock bolt.

There are also two types of round lead rubber bearing, but structure is different from high damping rubber bearing, besides, there are also rectangle type lead rubber bearing used on bridge. The rectangle LRB max size can be 1500x1500. Depending on the structure, the LRB isolators has two structure types, one is with connected plate on the isolator body top and bottom, and connected the rubber part with bolts, the other type is connect the top and bottom plates by vulcanization, which is to vulcanizating the isolator rubber body together to the top and bottom connection plates directly.

3.The Differences of Performance characteristics

Lead Rubber bearing

1), The LRB has stiffness before yield, and stiffness after yield, so the horizontal stiffness of the LRB will change before and after the lead core yields.

2), Its Having a high equivalent damping ratio helps to dissipate energy under seismic action.

3), The presence of lead core enables the LRB to exhibit good hysteresis performance under horizontal loads.

High Damping Rubber Bearing:

1), The HDR Provide stable vertical bearing capacity and horizontal restoring capacity.

2), They have a high equivalent damping ratio, reaching over 12%, which means they can dissipate energy more effectively under earthquake action.

3), It has low temperature dependence, making it suitable for different climatic regions.

Has good aging resistance and stable long-term performance.

In general, both HDR and LRB can provide theseismic isolation performancey, but they are different in designing, materials and performance, The designing engineers will choose the most suitable type of isolators based on specific engineering requirements and environmental conditions.