Key words, seismic isolator, seismic structure, LRB, HDR, elastomeric seismic bearing

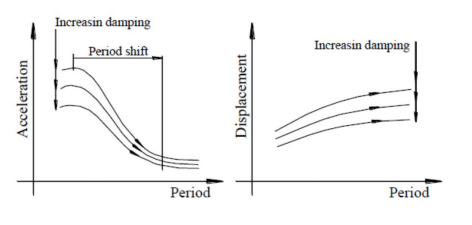

The desining work of seismic isolators for building and bridge normally needed to be finished by professional institute or designing company. The designing process is from the start of analysis the construction structure and local geological seismic conditions,such as The seismic intensity and acceleration in the region,The isolation system, due to its low horizontal stiffness, can extend the period of the upper structure to 2 seconds or even more than 3 seconds, greatly reducing the acceleration response of buildings caused by earthquakes

At the same time, the system can also utilize the nonlinear deformation of isolation bearings to absorb seismic energy, improve the damping ratio of the system, and thus reduce the force of earthquakes on buildings.

The principle of response spectrum for seismic isolation structures

The Design principle of seismic isolation is: Extend structural period → reduce acceleration response → reduce seismic shear Force → Structure reduces stress. Although the displacement response of the seismic isolation structure increases after extending the structural period, the isolation bearings can still By increasing the damping ratio of the system, the displacement response of the isolation structure can be suppressed. So we can see the seismic isolation structure is reliable, and seismic isolation structure included LRB, lead rubber bearing, high damping ruber bearing ,HDR, Friction Pendulum System , the designing principle show the different from elastomeric bearing pads, and other rubber bearing pad, even other steel type bearings. Seismic isolation structrue can be used on bridge and buildings construction.

Design process of seismic isolators:

The principle of designing seismic isolation bearings is to separate the building structure from the foundation through seismic isolation construction layer, so that the energy of earthquake action cannot be directly transmitted to the upper structure. This design can make buildings to move independently relative to the ground during earthquakes, significantly reducing the response acceleration of the structure, minimizing the generation of internal forces, and effectively protecting the safety of the structure. The design of seismic isolation bearings is a complex engineering problem that involves multiple fields such as earthquake engineering, materials science, and structural dynamics. The following are some key points in the design of seismic isolation bearings:

1.Extend the natural vibration period of the structure: Rubber isolation bearings extend the natural vibration period of the entire building by adding a rubber isolation layer, in order to reduce the seismic response of the upper structure. The general approach is to design a seismic isolation layer at the bottom of the building, and install rubber seismic isolation bearings on the isolation layer. The horizontal flexibility of the rubber seismic isolation bearings is used to form a flexible isolation layer, which absorbs and dissipates seismic energy, prevents and reduces the transmission of seismic energy to the upper structure, and ultimately achieves the goal of reducing seismic damage to the upper structure.

2.For elastomeric seismic isolator, like LRB , high damping rubber bearing, the purpsoe is to Increase rubber structural damping:

When multi-layer rubber bearings undergo shear deformation, rubber isolation bearings absorb energy through plastic deformation, while lead cores recover their mechanical properties through recrystallization at room temperature. The high damping isolation rubber bearings and lead core isolation rubber bearings have achieved functional integration of isolation devices and dampers, and this can greatly save building space and reduce costs. Rubber materials themselves have certain damping properties, so rubber seimiec isolators can absorb and dissipate seismic energy through the deformation of rubber, reducing structural vibration.

3. Material characteristics of Rubber isolation bearings :

Generally , it is made by alternately stacking thin steel plates and thin rubber plates, and then vulcanization at high temperature and high pressure. This structure can ensure vertical stiffness and seimic bearing capacity, while significantly reducing horizontal stiffness, making the building have seismic isolation performance. The excellent performance of rubber materials absorbs energy and reduces impact power during earthquakes. Rubber bearings are generally divided into rubber elastic bearings and rubber viscous bearings, so we can see , the rubber seismic isolator, LRB , HDR use the characteristics of elastic deformation or viscous damping to achieve seismic isolation.

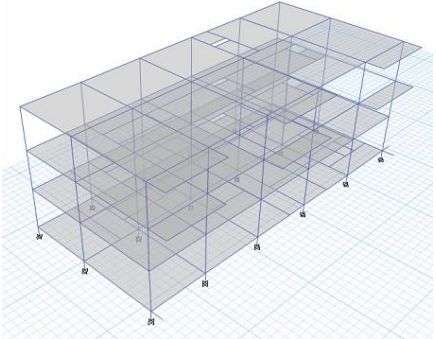

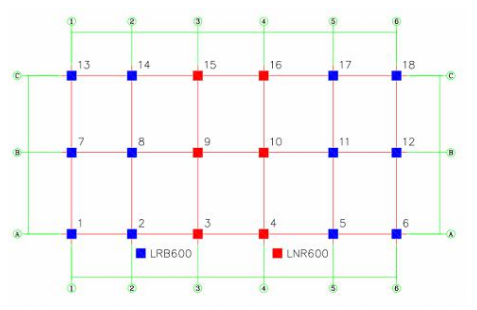

4. Structural design of LRB :

When designing rubber isolation bearings, it is necessary to consider the load distribution of the structure and the load effects under different working conditions, including factors such as strength and stiffness. Attention should be paid to the coordination between rubber materials and metal materials in design to avoid the occurrence and deformation of transition stiffness, as well as detachment under load.

So the structure desing of LRB should consider loading , stiffness, displacement and damping rate, and also to meet the building structure requests to lay the LRB and the foundation.

5. Optimization of seismic isolation effect:

In order to improve the seismic isolation performance of rubber bearings, various methods can be adopted to enhance the damping performance of rubber bearings. For example, vertically inserting a lead core with a purity of 99.9% into the center position of the rubber bearing to improve the damping performance of the bearing, or modifying the damping performance of the rubber material used in the bearing by adding fillers or other physical and chemical methods.

In summary, the design principle of rubber isolation bearings is to use the elasticity and damping characteristics of rubber materials to extend the natural vibration period of the structure and increase its damping, thereby reducing the impact of earthquakes on buildings and protecting structural safety.

Seismic requirements of LRB, HDR, and other seismic isolation bearings to the structure

| parts | Upper structure | Pier of seismic layer | Bottome structure |

Designing requirements | he seismic effect is determined by the maximum horizontal influence coefficient after seismic isolation and reduction, and the seismic structural measures are based on the reduced value (not reduced for those related to the vertical direction) | Under rare earthquake conditions, the loading capacity of the isolation structure meets the verification requirements | The seismic effect is determined according to the local level influence coefficient, and the seismic resistance should meet the requirements of embedded stiffness ratio and seismic bearing capacity calculation after isolation, and the shear bearing capacity calculation should be carried out according to rare earthquakes |