PTFE sliding bearing, which is produced based on laminated rubber bearing pad, bonding one PTFE plate on the top of it. It is used not only on bridge, but in factories, equipment, and other industry for loading and sliding purpose.

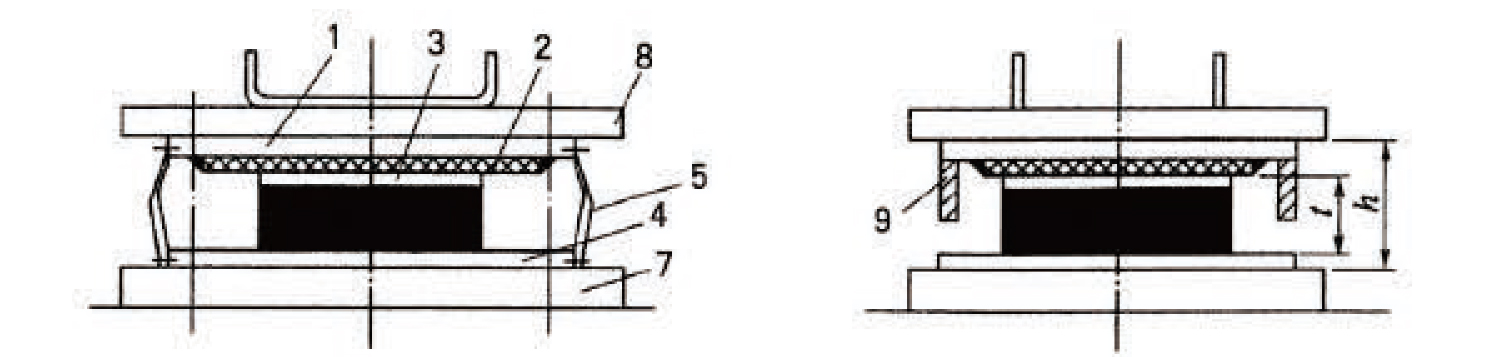

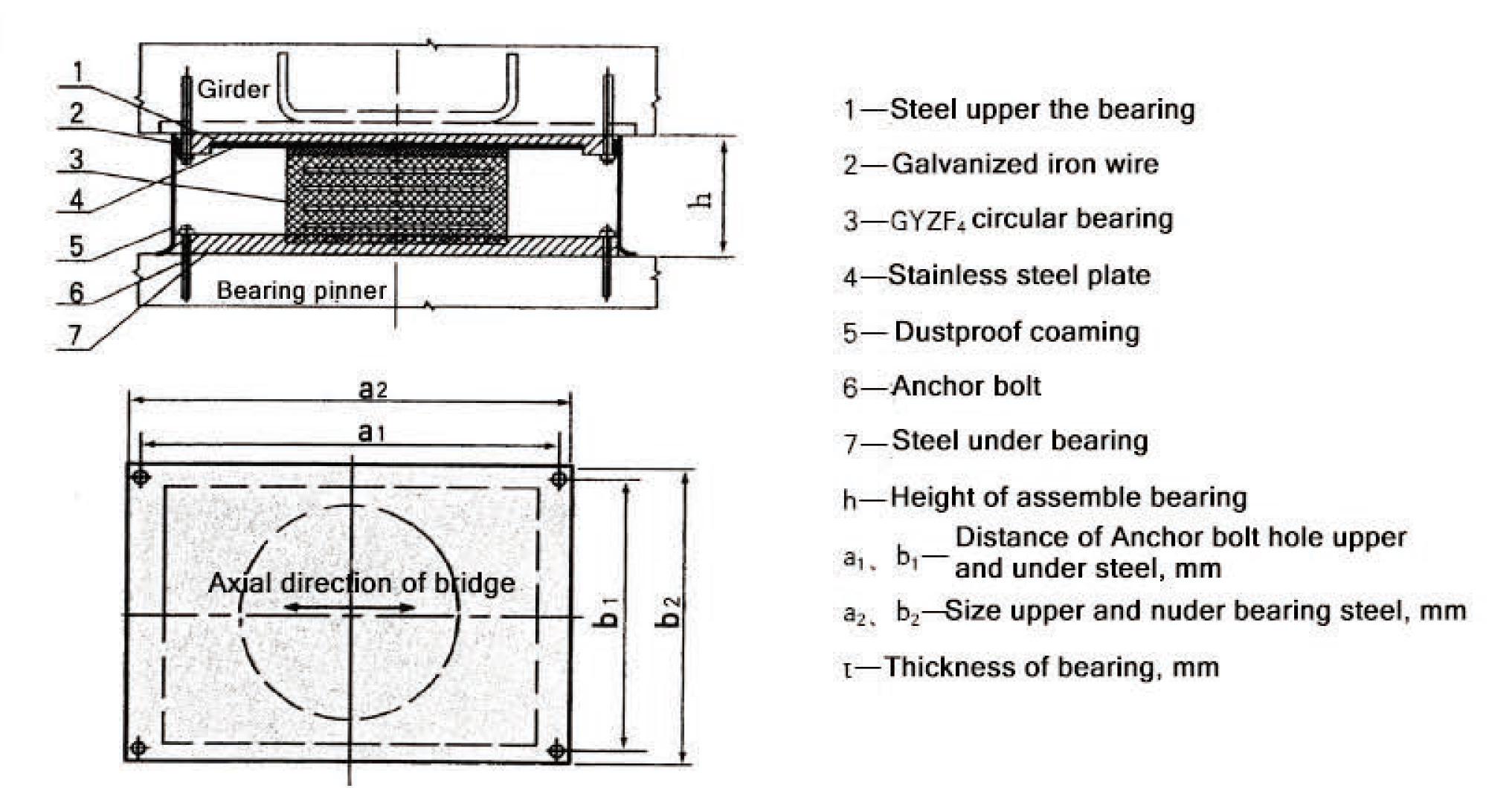

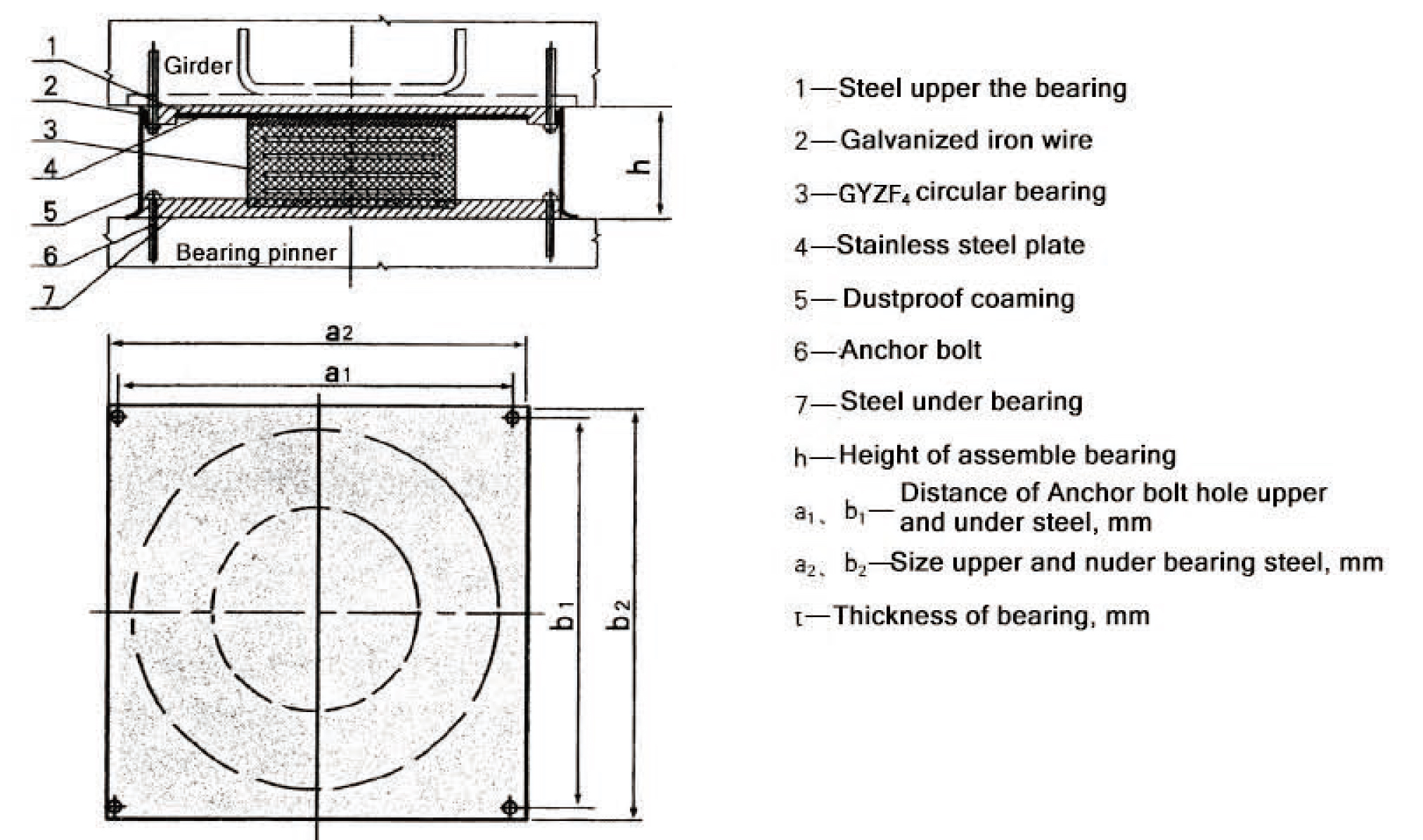

Classified by shape, there are rectangle and circle shape PTFE sliding bearing pad.The dimension range of PTFE bearing can be from 100mm to 800mm, and its designing bearing capacity can up to 5000KN. Normally, one assembly PTFE sliding bearing pad is composed of

1. Top steel plate,

2. Stainless steel plate,

3. PTFE sliding bearing,

4. Bottom steel plate,

5. Dust cover,

6. Anchor bolts,

7. Supporting pads of bridge bearing,

8. Embedded steel plate at the bottom of the beam,

9. Guide plate

The main calculation of PTFE rubber bearing pad,

The calculation technical parameters of PTFE bearing pads normally are vertical loading capacity, shape factors, rotation, because it is sliding type bearing, if it is rectangle shape sliding bearing pads, there are two installation situations: guided sliding bearing pad, and free sliding bearing pads, the installation structure of PTFE sliding bearing as bellow

The installation of PTFE bridge bearing pads

There are two situations to be connected with supporting pads. One is to install the PTFE bearing pads directly on the supported pads , Leveling and bonding with epoxy mortar, gaps or deviations due to compression is not allowed. The other installation method is to set an embedded steel plate on the top of supporting pad, and connected to the steel mesh in the cushion stone. A 5mm deep groove should be set in the center of the steel plate, and the groove should be 5mm larger than bearing pad size.

How to install the PTFE bearing pad on the beam?

Construction of cast-in-place beams:The top steel plate can be welded and anchored, and the steel bars can be cast on site and connected to the beam body.

Prefabricated beam construction: The upper steel plate can be bonded to the beam body using epoxy resin mortar. If there are embedded steel plates at the bottom of the beam, they can be connected by bolt connection and welding methods.