1.The introduction of LRB

LRB was developed in 1975 by New Zealand scholar. The lead rubber bearing structure is injecting a lead rod of a certain diameter vertically into the middle of the laminated rubber bearing,elastic properties of lead cores during vibration can reach the effect of dissipating seismic energy. Because the yield force of lead core is low, and lead core has good fatigue characteristics under plastic deformation, so it is considered as a good damper to be used on LRB.

The lead core must be securely fastened in the hole and slightly squeezed into the rubber layer,The lead core must be securely fastened in the hole and slightly squeezed into the rubber layer. So the diameter of lead core should be larger than the rubber layer hole in the center, and using a pressure machine to press the lead core to the laminated rubber bearing hole.

When the horizontal deformation occurs of the rubber bearing, lead core is forced to have the shearing deformation because of the steel plated reinforced. Lead rubber bearings have excellent hysteresis characteristics, the initial shear stiffness can reach more than 10 times of normal laminated rubber bearing pads, and the stiffness of yielding is closed to normal elastomeric bearings. Because of the simply structure and good performance of lead rubber bearing, it is widely used in bridge and building seismic construction, we have many overseas projects choose to use LRB too.

2.Structure of LRB

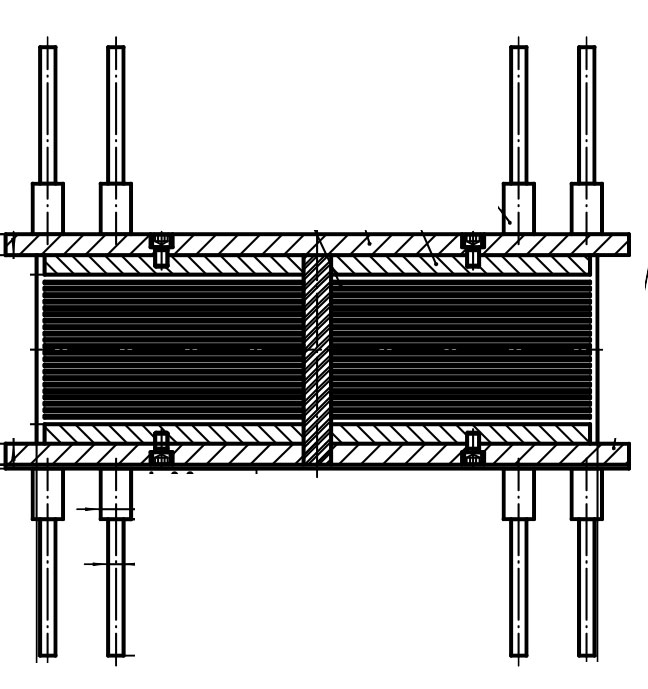

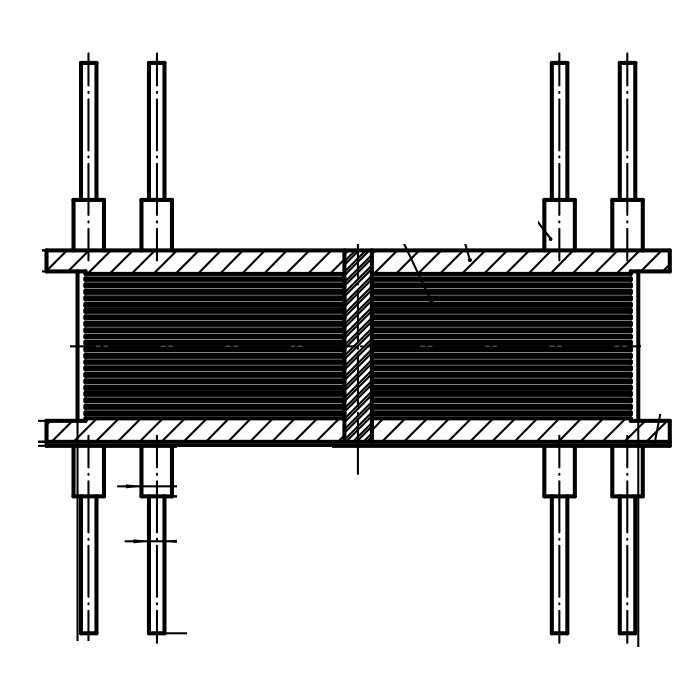

There are two types of structure of LRB. One type is laminated rubber pads with lead core injected insided, and the connection steel plates of top and bottom are vulcanized directly on the rubber pads, the other type structure is designed to connected steel plates with high strength bolts, and there are sealing plates to connected with top and bottom plates with bolts. Details as bellow:

3.The technical designing and work principle of lead rubber bearing

Depending on different requests of the project parameter, the LRB can be stacked structure,manufacturing process, rubber formula design to meet the requests as vertical stiffness, damping rate, Durability,Anti overturning ,displacement,,,etc.

Good performance of LRB

1), Compression performance, under the vertical loading, the steel plates and rubber modulus of laminated lead rubber bearing are very different from the Lateral deformation coefficient,but the steel plate will generate lateral constraint force, make the rubber internal to be at the status of three direction force, so the LRB vertical loading is much larger than rubber itself, it is closed to the same cross section area of reinforced concrete, so we can see the vertiacl loading of LRB is big and can be design depending on steel plate area.

2), Durability and service life of LRB. During the LRB period, because of the aging and creep, the machanical property of lead rubber bearing may generate different impacts. According to study, after 60 years, the horizontal stiffness will rise 10-20%, the horizontal ultimate deformance will reduce 10%, so we should consider these factor during designing to reduce aging and creep impact to the LRB. About creep experiment show that rubber creep ratio is 10% of the total rubber thickness after 100 years.

So we can see that the service life of LRB is long, almost the same as the building.