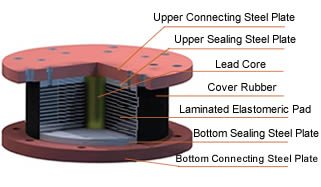

Lead rubber bearing, applied to building and bridge constructions, is a practical and cost-effective choice for seismic isolation. It is composed of laminated elastomeric bearing pad, top and bottom sealing & connecting plates and lead plug inserted in the middle of the bearing as shown in the following picture.

Component of lead rubber bearing

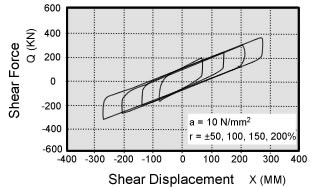

With stable bilinear behavior

● Stiff and strong in vertical direction but flexible in horizontal direction.

● Absorb earthquake-generated force by changing the bearing’s shape.

● Allow the buildings to retain their original shapes and position owing to the high elastic force of rubber.

● Capable to adjust damping amount just by changing the number of lead plugs.

● Excellent vertical load capacity ranging from 5 tonf to 2000 tonf.

● Reduce the ground acceleration by extending the structure vibration period.

● High durable and elasticity of the rubber part - not suffer any damages during and after earthquake.

● Easy to install without a separated damper.

● Low maintenance.

● With stable bilinear behavior shown as the above picture.

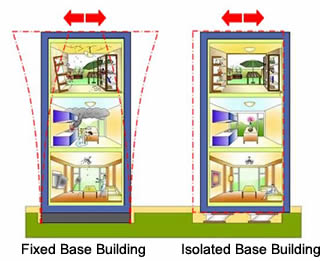

Lead rubber bearing avoids deformations and damages to buildings.

During the earthquake, the un-isolated building will vibrate back and forth in varying directions due to the inertial forces and result in deformation and damages of the building. In contrast, the base isolated building will also displace but remains its original shapes and avoid damages - that is because the lead rubber bearing effectively dissipates the inertial force upon the building, extends the building’s period of vibration and decrease the acceleration of the building.

The lead plug will slid with laminated rubber during earthquake but convert this energy of movement to heat so that it efficiently reduces the inertial force upon the building, which slow the vibration of the building. Meanwhile, the rubber part will preserve its original shape due to high elasticity.

Contact us for more information about lead rubber bearings.