1. Installation preparation and precautions

When using this series of bearings, the concrete grade of the bearing pad stone shall not be lower than C40 (local compressive strength shall not be less than 20MPa).

The height of the cushion stone should consider the convenience of installation, maintenance, and necessary replacement of the pot bearing, and effective drainage measures should be taken around the bearing.

The height difference between the four corners of the top surface of the cushion stone shall not exceed 2mm. Before installation, reserved holes should be left at the pad stone or pier area according to the main dimensions of the support and the plane connection dimensions in the weight table. The diameter of the reserved hole is the sleeve diameter plus 60mm, and the depth of the reserved hole is the sleeve length plus 60mm. The deviation of the center distance and diagonal length of the reserved holes shall not exceed 10mm.

When installing bearings for prefabricated simply supported beam bridges, a force measuring jack should be used as a temporary support to ensure that each pivot point is reversed

The difference between the force and the average reaction force of the four pivot points shall not exceed ± 5.

During the installation process of the pot bearing, it is not allowed to dismantle the beariing arbitrarily. But before the prefabricated beam is erected or the cast-in-place beam begins to be prestressed and tensioned ,The temporary locking connection device must be removed.

After removing the pot bearing packaging, the pot bearings should be kept clean and measures such as collision prevention, pollution prevention, and heat prevention should be considered.

When pre embedding steel plates, sleeves, and bolts at the bottom of prefabricated support beams, the accuracy of the connection dimensions with the upper pot bearing plate should be ensured

The deviation of heart distance and diagonal length shall not exceed 1mm. And the plane of the embedded steel plate surface in contact with the top surface of the support at any position

The degree should not exceed 1/1000.

Pot bearing displacement and angle pre deviation should be approved by the manufacturer and bridge design institute. And completed under the guidance of the manufacturer.

It is recommended to provide a pre deviation amount when signing the contract. The pre deviation amount should be set and locked before the product leaves the factory.

2.Installation steps for railway pot bearings

2.1 Before lifting the beam, remove the pot bearing packaging iron sheet and clean the rivets on the surface of the pot bearing, and then install the pot bearing.

At the bottom of the prefabricated box girder. There should be no gap between the upper pot bearing plate and the pre embedded steel plate at the bottom of the beam. If there is a gap, pressure should be applied Fill with grouting method.

2.2 Chisel the surface of the support pad stone at the position where the pot bearing is in place, remove debris from the reserved holes, install grouting templates, and use Soak the surface of the cushion stone with clean water. The grouting template can be made of prefabricated steel formwork, with a layer of 4mm thick rubber leak proof strip on the bottom surface, fixed to the top surface of the supporting pad stone through expansion bolts.

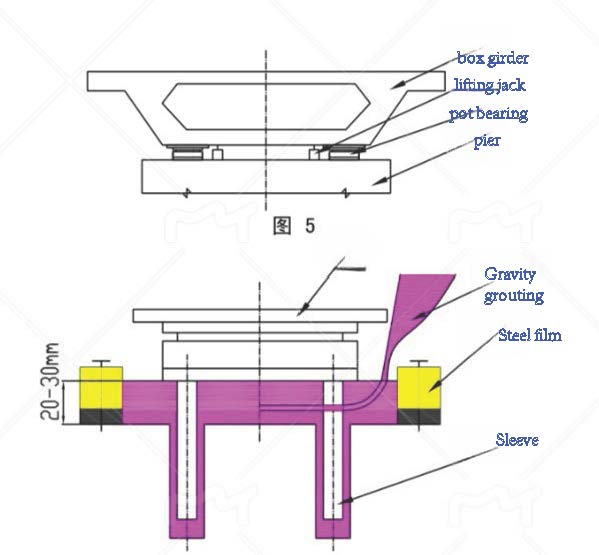

2.3 Hoisting prefabricated box beams, with pot bearings, place the box beams on temporary support jacks, and adjust the beam body and pot bearing through the jacks Seat to the design position and elevation, as shown in Figure 5. Ensure that there is a gap of 20mm and 30mm between the bottom plate of the pot bearing and the top surface。

3 Installation steps for pot bearings for cast-in-place continuous beam bridges

3.1 Follow the installation steps 2.2 for prefabricated simply supported box girder bridge bearings. Wedge the four corners of the pot bearing with steel wedges and Adjust the pot bearing to the design position and elevation. Ensure that there is a gap of 20mm and 30mm between the bottom plate of the pot bearing and the top surface of the pot bearing pad stone. In order to infuse non shrink high-strength infusion materials, the performance requirements of infusion materials should meet relevant requirements.

3.2 Follow the steps for installing pot bearings for prefabricated simply supported box girder bridges as stated in 2.4

3.3 After the final setting of the grouting material, remove the steel formwork and four angle steel wedges, check for any leakage, and if necessary, inspect the leakage

Perform grouting and fill the gaps left by the steel wedge block after extraction with mortar. Tighten the anchor bolts of the lower pot bearing plate, and complete the construction of the beam body.After tensioning, remove the temporary locking connection device of the support in a timely manner before prestressing. And install the support panel.

4 Installation steps for bearings for prefabricated multi piece T-beam bridges

4.1 Before lifting the beam, remove the pot bearing packaging iron sheet and clean the rivets on the surface of the pot bearing, and then install the pot bearing

There should be no gap between the pot bearing plate at the bottom of the prefabricated T-beam and the embedded steel plate at the bottom of the beam. If there is a gap, pressure should be applied

Fill with grouting method.

4.2 Remove debris from the reserved holes on the surface of the support pad stone where the chiseled pot bearing is in place, and use water to clean the surface of the support pad stone

Wet.

4.3 Before dropping the beam, lay a layer of 20mm and 30mm thick dry hard non shrinkage mortar on the top surface of the supporting pad stone, and reserve corresponding holes

Also fill it with mortar. The top surface of the mortar is laid in a shape slightly higher in the middle than the surrounding areas, and after the T-beam is placed in place, adjust the support to the design position

Positioning and elevation. After being in place, use temporary brackets or wooden pads to support and block both sides of the beam to prevent it from tilting.

4.4 When installing multiple T-beams, the two T-beams at the center of the line should be lifted first. And after the two T-beams are lifted into place

Timely weld the connecting steel bars between the two T-beams, and then lift the remaining T-beams symmetrically from the center to both sides. In every T

After the beam is in place, temporary supports should be set up and corresponding connecting steel bars should be welded in a timely manner.

4.5 After pouring concrete for the transverse partition between multiple T-beams and reaching strength, the temporary locking connection of the support should be removed in a timely manner

Device. And install the pot bearing panel.