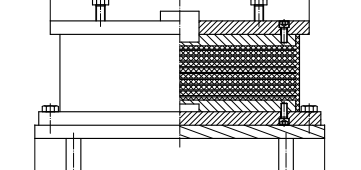

Seismic sliding bearings include elastic sliding bearings and rigid sliding bearings.

Overview

Seismic sliding isolation works by installing a sliding layer between the superstructure and the foundation, limiting the seismic forces transmitted to the superstructure to a constant, controlled level, thereby protecting the structure. The dynamic characteristic of this system is that once the building begins to slide, the stiffness of the isolation layer drops to zero, causing the natural vibration period of the system to approach infinity. This effectively avoids resonance effects from any seismic waves. Additionally, the friction generated during sliding dissipates seismic energy through work, increasing system damping and reducing the seismic response of the superstructure.

Performance of Seismic Sliding Bearings

The performance of seismic sliding bearings includes vertical performance, horizontal performance, sliding performance, and aging resistance.

Vertical Performance

1.Vertical Stiffness

Vertical stiffness is determined through compression tests based on the thickness-to-diameter ratio of PTFE (polytetrafluoroethylene) and the vertical stiffness of the rubber bearing component. Generally, the stiffness of the rubber component dominates, so the vertical stiffness of elastic sliding bearings is taken as that of the rubber part. For rigid sliding bearings, the stiffness is also derived from the rubber layer.

Sliding bearings cannot withstand tensile forces, resulting in zero tensile stiffness.

2. Vertical Load Capacity

The load-bearing capacity depends on the strength of the PTFE material. Under normal conditions, PTFE exhibits high compressive strength. Design standards specify that the allowable compressive stress under gravity loads should not exceed 25 MPa, while the instantaneous compressive stress during seismic events should remain below 50 MPa.

3.Horizontal Performance

Horizontal Stiffness

Before sliding, sliding bearings exhibit certain horizontal stiffness.For elastic sliding bearings, the horizontal stiffness equals the shear stiffness of the rubber component.

For rigid sliding bearings, the rubber component is horizontally rigid, so stiffness depends on the combined rigidity of steel components (e.g., pot bearings). This stiffness is typically very high and can be assigned a large fixed value in design analyses.

Static Friction Coefficient

The static friction coefficient is derived from the initial peak friction during sliding (see Figure 5-6) and is determined via dynamic loading tests under varying compressive stresses and sliding velocities. It is slightly higher than the dynamic friction coefficient. Static friction occurs only once during initial sliding and minimally impacts the superstructure. However, excessively high static friction coefficients may induce torsional responses under uneven vertical loads, necessitating careful design and construction measures.

Dynamic Friction Coefficient

The dynamic friction coefficient remains consistent during bidirectional sliding and is determined experimentally. In seismic analyses, it is treated as a fixed value despite dependencies on stress, velocity, and temperature.

For PTFE and polished stainless steel systems, the coefficient ranges between 0.05–0.12 under standard compressive stress.

Coatings on stainless steel can reduce friction to 0.02–0.05.

Research on PTFE-stainless steel friction reveals:

1.Friction decreases with increasing compressive stress but stabilizes beyond a threshold.

2.Friction rises sharply with sliding velocity until stabilizing at ~150 mm/s.

3.Friction decreases at higher ambient temperatures.

4.Dynamic friction decreases over repeated cyclic loading before stabilizing after multiple cycles.

Aging Resistance

Aging refers to changes in material consolidation and friction coefficients.

Consolidation: Long-term loads may bond sliding materials to sliding surfaces. In a case study of a building with elastic sliding bearings (PTFE + polished stainless steel) 9 years after completion, the dynamic friction coefficient measured 0.05, only slightly higher than the pre-construction value of 0.04, demonstrating excellent aging resistance.

No. | Performance | Test Item | Requirement |

1 | Compression Performance | Vertical Compression Stiffness (K) | Permissible deviation: ±30% |

2 | Shear Performance | Initial Stiffness (K₁) | Permissible deviation: ±15% |

3 | Dynamic Friction Coefficient | - Low-friction bearings: Permissible deviation ±50% | |

4 | Shear Performance Correlations | Stress Dependency | - Reference compressive stress: Design compressive stress |

5 | Loading Velocity Dependency | Reference loading velocity: 0.4 m/s | |

6 | Cyclic Loading Dependency | - Reference cycle: 3rd cycle | |

7 | Temperature Dependency | - Reference temperature: 23°C | |

8 | Compression Performance Correlations | Stress Dependency | Vertical compression stiffness must exhibit consistent behavior

|

9 | Ultimate Performance | Horizontal Ultimate Performance | 1. Under design compressive stress, no failure, buckling, or overturning shall occur before reaching the design maximum horizontal displacement. Components of elastic sliding bearings must remain intact. |

10 | Vertical Ultimate Compressive Performance | ||

11 | Durability | Aging Performance | Variation in initial stiffness (K₁) shall not exceed 30%. |

12 | Creep Performance | Creep deformation over 60 years shall not exceed 10%. |