Bridge bearings are one of the most important part in the bridge structure construction, the two main functions are: transmitting loads from the upper structure; Ensure that the structure can deform freely under temperature changes, concrete shrinkage and creep, and load, so that the actual stress situation of the upper and lower structures conforms to the static diagram of the structure. Elastomeric bearing pads can meet this requirement well, it can adapt the deform of any direction, and it also reducing the seismic dynamic effects on the upper and lower structures due to the elasticity of rubber, it is very beneficial for earthquake resistance. Therefore, it has been widely used in bridges both domestically and internationally.

1.The Types Of Rubber Bearing Pads

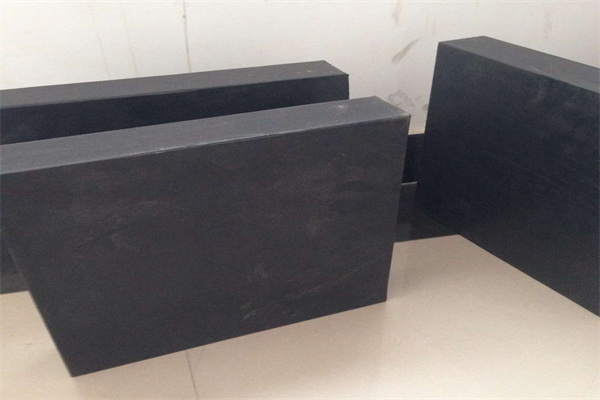

The Normal Structure Ruber Bearing Pads.

Structural features: Ordinary rubber bearings are composed of multiple layers of reinforced steel plates and rubber sheets. Thin steel plates are used as the reinforcement layer, and the reinforced steel plates are firmly bonded to the upper and lower rubber layers through pressure vulcanization with adhesive. The reinforced steel plates embedded between the rubber sheets can effectively prevent lateral expansion of the rubber sheets, thereby significantly improving the compressive strength of the rubber sheets and the compressive stiffness of the bearing. The thickness of the reinforcing steel plate is generally not less than 2mm, and the thickness of the middle layer rubber sheet is not less than 2.5mm.

2.Deformation mechanism: Ordinary elestomeric bearing pads achieve beam rotation through uneven compression of rubber sheets, and achieve beam horizontal displacement through shear deformation of rubber sheets. Therefore, there is no distinction between fixed type rubber bearing and movable rubber bearings, and rubber sheets of different thicknesses can be used to adjust the horizontal force and displacement transmitted by each rubber bearing.

3. Application and types Of Rubber Bearing Pad

Because the bridge bearing pad horizontal displacement is from the shearing deformation,The allowable shear deformation of rubber sheets is relatively small, so the horizontal displacement of ordinary plate type rubber bearing pads is relatively small, so they are only suitable for highway bridges and the bridge spans normally are less than 30m and are small displacement.

There are type shapes of rubber bearing pads, round type and rectangle type.Orthogonal bridges use rectangular plate rubber bearings, while curved bridges, sloping bridges, inclined bridges, and wide bridges use circular plate rubber bearings;

The rubber bridge bearing pad are devided two types depending on materials and temperatue, there are normalr teperature rubber bearing and cold resistant rubber bearing,Produced using chloroprene rubber (CR), suitable for temperatures ranging from -25 ℃ to 60 ℃; Cold resistant rubber bearings are made of natural rubber (Nit) and are suitable for temperatures ranging from -40 ℃ to 60 ℃.

4.Slope shaped plate rubber bearing

Slope shaped bridge rubber bearings, it has the functional characteristics of ordinary bridge rubber bearings, it can also adjust the slope of bridges. The bearings are uniformly stressed, without stress concentration, and there is no void phenomenon within the adaptation range. They can reliably transfer the load from the upper structure to the lower structure. Suitable for situations that the bottom of the beam has a slope of 1% to 4%.

5. The sperical tap round rubber bearing pad

The structure charicteristics,to add a rubber sperical tap on the top of elastomeric bearing pads, the height is normally 4-13mm, this structure is nearly to point support, so sperical tap can be used to adjust the center position, this structure can avoid the situlation of bias and detachment phenomena, and make the installation process easier.

6.PTFE sliding rubber bearings

(1) Structural features: The PTFE sliding plate rubber bearing is a layer of PTFE plate (2-4mm) pasted on the top surface of the ordinary plate rubber bearing, and a stainless steel plate is set at the bottom of the beam for relative sliding motion. Due to the low friction coefficient between polytetrafluoroethylene plate and stainless steel, the horizontal displacement is large and can be used as a movable support.

(2) Application: The PTFE sliding rubber bearing has a large horizontal displacement, so it is suitable for large-span simply supported beams, continuous beams, and bridges with continuous bridge decks. It can also be used as a sliding block for continuous beam top pushing and T-shaped beam lateral movement.

7.The Installation Of Elastomeric Bearing Pads

1) ,The short side of rubber bearing pads should be installed along the bridge direction

2) The PTFE sliding bearing pads should be installed horizontally,The PTFE sliding rubber bearing pads shall not be installed on the bottom surface of the support, and the stainless steel plate in contact with the PTFE sliding plate shall not be installed on the bridge pier or abutment pad stone

There should be a support stone at the place installed the bridge beairng pads,The size of the supporting pad stone plane should be determined based on local pressure calculation. The length and width of the pad stone should be increased by about 50mm compared to the corresponding size of the rubberbearing pads, and its height should be above 100mm. It should also be considered to facilitate the replacement of the rubber bearing pad.

.

There should be Reinforcement mesh at the inside of bearing bearing support stone, the space better is 50mmX50mm while the bar dia is 8mm, There should be vertical steel bars extending into the bearing pad stones inside the bridge piers and abutments, and the concrete strength grade of the bearing pad stones should not be lower than C30.

The surface of the bearing suport stone should be flat,clean,dry, and no sand, the top of the suport stone height, After installation, it is necessary to ensure that the bridge bearing pad is in close contact with the upper and lower structures, and there should be no looseness.Heavy vehicles should be avoided from passing through if the whole structure of the beam and slab not finished.

8.Conclusion

Because there are many outstanding advantage of bridge rubber bearing pads, and it is widely used, so at the period of designing, the selection of plate rubber bearings should be emphasized, and the installation of plate rubber bearings should be emphasized during construction ,to ensure a long service life and normal functionality of the elatomeric bearing pads.