There are many types of bridge pot bearing, as the usage type, there are pot bearings used on highway bridge and pot bearings used on railway bridge. For the highway bridge pot bearing and railway bridge pot bearing, there are also many different types,like Tensile and pull-out resistant pot type rubber bearings,anti-seismic pot bearing, special pot bearing used on railway. There are also normal temperature type pot bearing, and cold resistant type pot bearing,which can be used in temperature range of -45-60℃,depending on different bridge requests, pot bearing designing has been being improving.

The structure of bridge pot bearing

Design principle of bowl type rubber bearing structure

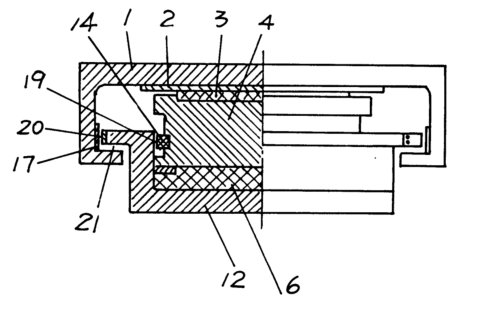

The elastic rubber pad block in the semi enclosed steel pelvic cavity has fluid properties under triaxial stress, thus achieving the rotation of the upper part of the bridge. At the same time, the low friction coefficient between the PTFE plate on the middle steel plate and the stainless steel plate on the upper seat plate achieves the horizontal displacement of the upper structure, so that the shear by the pot bearing is no longer completely borne by the rubber, but by the slip between the PTFE plate and stainless steel. From the experimental data, it can be seen that the compressive elastic modulus of rubber in a three-dimensional constrained state is 50000kg/cm2, which is nearly 20 times higher than the compressive elastic modulus without lateral constraints. Therefore, the bearing capacity of the bowl shaped bearing is greatly improved, it solves the limitation of the bearing capacity of the rubber bearing and can meet the requirements of large support reaction force, large horizontal displacement and rotation.

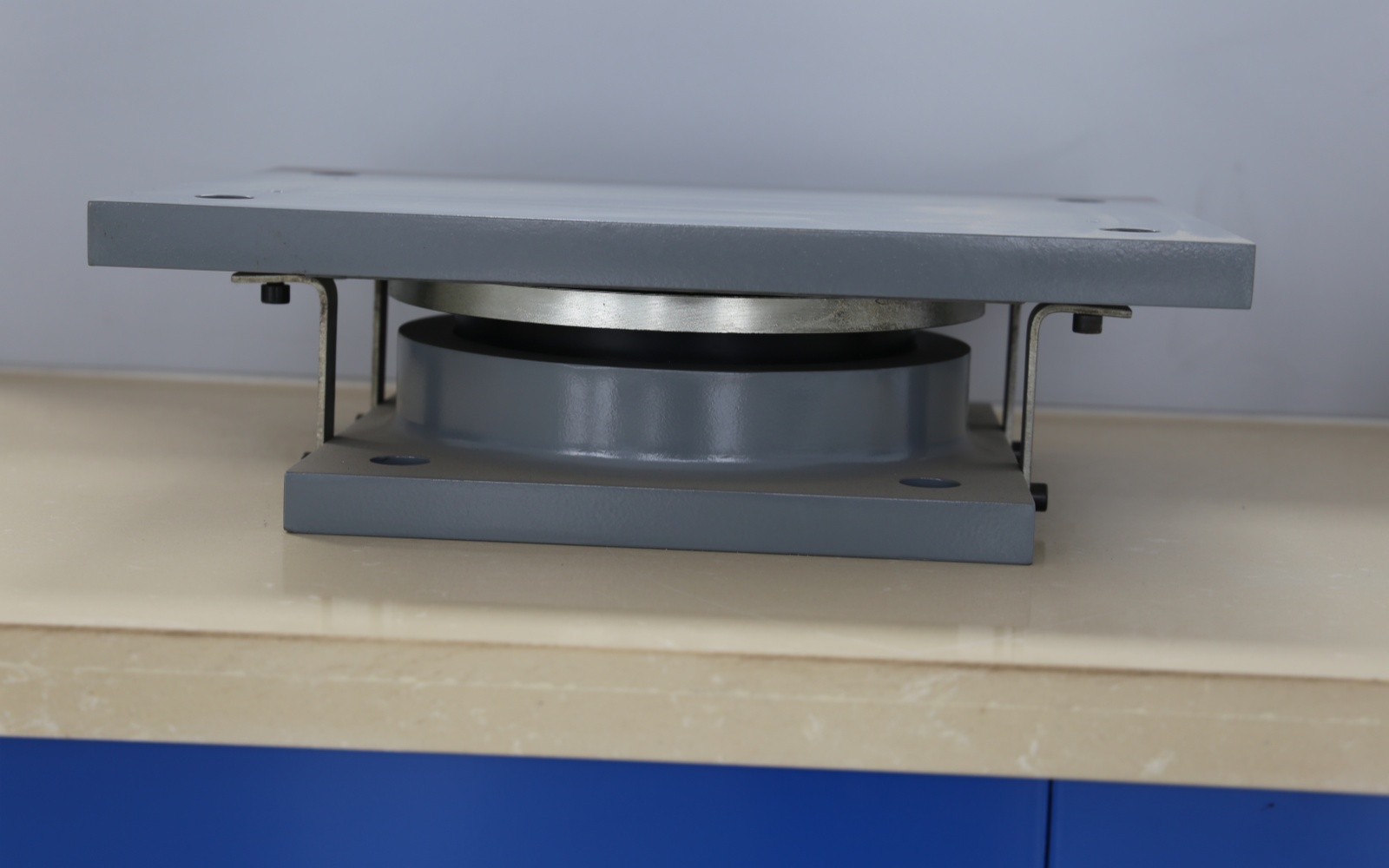

According to the installation places on the beam, pot bearing are designed three types, fixed type pot bearing, guild type pot bearing, and free sliding type pot bearing.In different projects, the arrangement of pot bearings on the bridge beams are different.

But how we choose the pot bearing type and how to design pot bearing? Normally, the pot bearing are designed depending on technical parameters requested from the bridge designing,there are parameters are vertical loading capacity, the Pier and abutment dimensions which is the max limited pot bearing, including the max height, parameters also includes displacement of guild type pot bearing and free sliding pot bearing, rotation, etc..

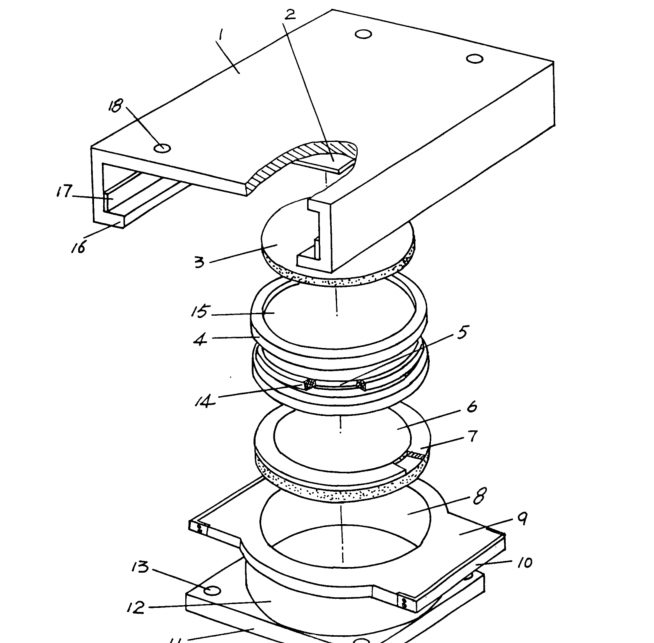

There are also some special type pot bearing , like tensile pot bearing, it is a new developed type bridge bearings, now are widely used on railway bridge and highway bridge, and The elevated bridge in the city, as well as various large overhead bridges,the tensile pot bearing structure as bellow

1. The top plate, which is connected with bridge beam by bolts.

2. The upper plate, which is stainless plate, welded to the top plate,

3. PTFE plate, it has a buffering and wear-resistant effect. thePTFE plate , also called sliding plate , its one side next to stainless plate, the other side is stuck in a pot as parts 5 and 15.

4. The bottom pot part 12 is welded on the bottom plate 11, and the bottom plate 11 of pot bearing will be connect to the pier of the bridge by bolts.

This structure of tensil pot bearing also has seismic effect, it can be also used on seismic bridge, it is a import development of seismic pot bearing.