Home < News < Selection And Structural Design Requirements For Bridge Bearings Used In Rail Transit Bridges

1.General Provisions of Bridge Bearings Used In Rail Transit Bridges

1.1 Scope of Application

We specifies the selection and structural design requirements for bearings used in urban rail transit bridges, applicable to various types of bearings commonly used in urban rail transit bridges.

1.2.Safety performance requirements

The bridge bearing used for urban rail transit bridges should have sufficient strength and stability to ensure the long-term safe, fast, and smooth operation of trains on urban rail transit bridges.

1.3 Service life requirements of the city rail bridge bearing

The bridge bearings used for urban rail transit bridges should be designed for durability according to the requirement of a service life of 50 years.

1.4 Maintenance and replacement requirements

The bridge bearings used for urban rail transit bridges should be regularly maintained and repaired, and the possibility of replacing the bearings should be considered in the design.

2.Selection Of Bridge BearingsUsed On City Rail Bridge

2.1 Bridge bearing type

Common types of bearings for urban rail transit bridges include plate type rubber bearings (including PTFE plate sliding rubber bearings), bridge pot rubber bearings, and spherical steel bearings. When selecting other types of new bridge bearings, such as seismic isolation bearings, professional technical evaluation of the product should be conducted before use.

2.2 Brideg Bearing Used On T-beam

Multi piece T-shaped simply supported beam bridges used for urban rail transit should use plate type rubber bearings. The span of T-shaped simply supported beams should not exceed 25m, and pot rubber bearings should be preferred for T-shaped simply supported beam bridges with spans greater than 25m.

3.Bearings for Box Beams

3.1 For prestressed concrete box type simply supported beams and medium to small span box type continuous beam bridges used in urban rail transit, it is recommended to prioritize the use of pot rubber bearings.

For large-span box type continuous beam bridges (LP ≥ 40m) used in urban rail transit, spherical steel bearings should be preferred, and pot rubber bearings can also be used.

Bearings for steel beams and steel-concrete composite beams

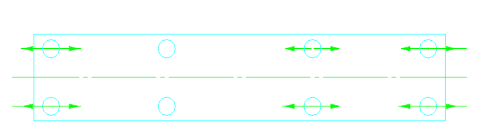

For large-span steel beams and steel-concrete composite beam bridges used in urban rail transit, spherical steel bearings should be preferred, and pot type rubber bearings can also be used. During installation, the bridge bearnig should be inverted, that is, the plane sliding surface of the bearing should be set on the pier, and the rotation center of the brideg bearing should coincide with the axis of the beam support.

3.2 Bearings for bridges in earthquake areas

Bridges located in earthquake prone areas should use seismic isolation bearings when the local peak ground acceleration is greater than 0.2g. The seismic isolation bearings should be used in conjunction with anti falling beam construction measures. The seismic horizontal force borne by the support should be determined based on the peak ground acceleration. The peak ground acceleration should be determined based on the seismic response spectrum of the area where the bridge is located. Urban rail transit bridges using seismic reduction and isolation bearings must undergo seismic response analysis of the entire bridge (including bearings) and calculate the safety of trains on the bridge during earthquakes.

4.Design DisplacementOf Bridge Bearing

The design displacement of the main displacement direction (along the bridge direction) of the bridge rubber bearing is divided into three levels: ± 20, ± 30, and ± 40mm. The design displacement of the main displacement direction (along the bridge direction) of the PTFE sliding rubber bearing is divided into two levels: ± 50 and ± 100mm.

The design displacement of pot rubber bearings and spherical steel bearings in the main displacement direction (along the bridge direction) is divided into 5 levels: ± 50, ± 100, ± 150, ± 200, and ± 250mm, and the design displacement in the transverse bridge direction is ± 10mm.

The design angle between the plate rubber bearing and the PTFE sliding rubber bearing shall not be less than 0.012rad. The design turning angle of pot rubber bearings and spherical steel bearings shall not be less than 0.020 rad.

5.Design Horizontal ForceOf Bridge Bearings

The design horizontal force of the bearing limit direction is divided into two levels: 15% and 30% of the design vertical bearing capacity; The design horizontal force of the limit direction of the earthquake zone support should be determined based on the calculation of the peak ground acceleration; The design horizontal force for the displacement direction of the movable bridge beairng is 5% of the vertical bearing capacity .

6.Construction Requirements

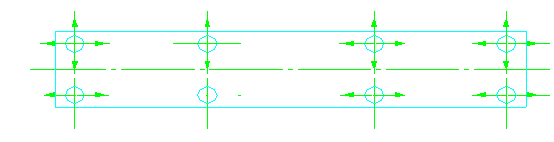

The bridge bearings used for urban rail transit bridges should be equipped with necessary lateral limit structures to meet the requirements of safety and comfort during rapid train operation. When the maximum speed of the train reaches 120-160km/h, the allowable lateral displacement of the bearings is ± 1mm.

The connection between the beam bottom and the bridge bearing of concrete bridges used in urban rail transit should be equipped with steel plates at the beam bottom. The thickness of the steel plate at the beam bottom should not be less than 20mm, and the bottom surface of the steel plate should be machined with a flatness △ Z ≤ 0.0003Dp or 0.2mm, whichever is larger. Dp is the diagonal length of the steel plate at the bottom of the beam.