The bridge elastomeric bearings produced by our company are manufactured and inspected in strict accordance with international and national standards.

Product Detail

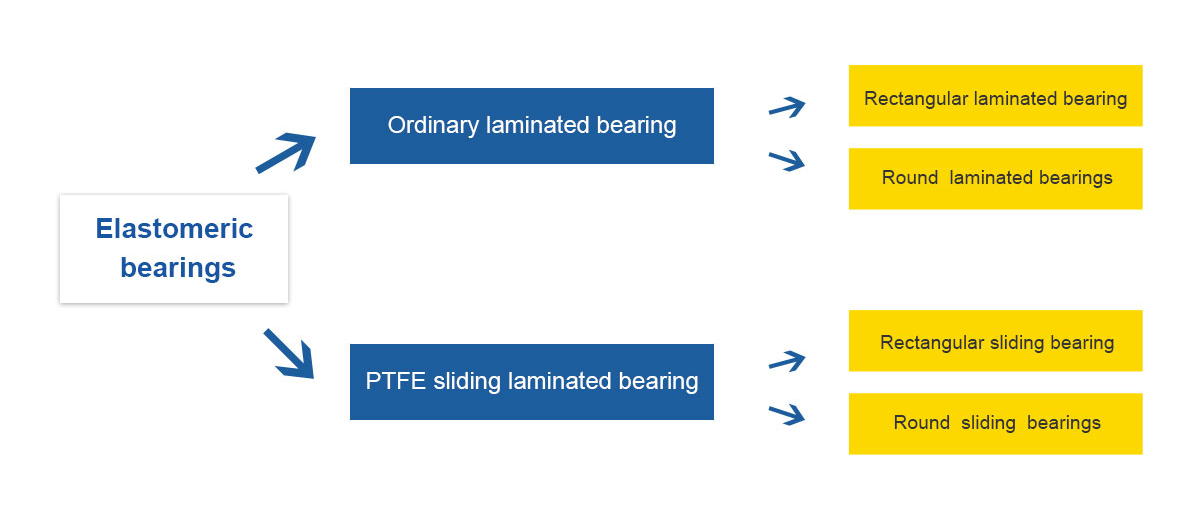

1. Classification of Laminated bridge bearings

(1) Classification by structure

(2) Classification by material and applicable temperature

Normal temperature rubber bearing, chloroprene rubber(CR) Applicable temperature -25℃ ~ 60℃

Cold resistant rubber bearing Nature rubber(NR) Applicable temperature -40℃ ~ 60℃

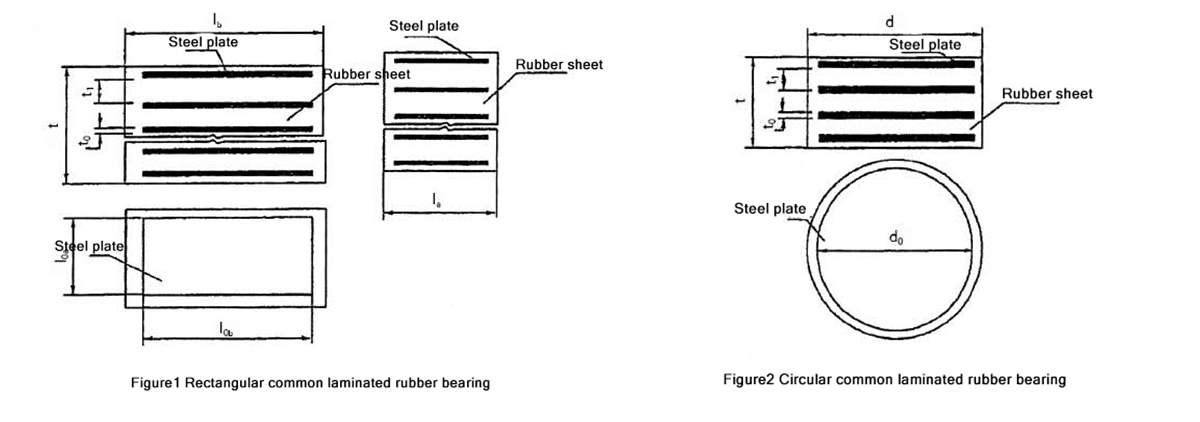

Rectangular (round) bridge rubber bearing

(1) Performance of elastomeric bearing pad

There is enough vertical stiffness to bear vertical load, and good elasticity of the elastomeric laminated bearings to adapt to the rotation of beam end; There is also a large shear deformation to meet the horizontal displacement of the superstructure.

(2) Features of elastomeric bearing pad

Bridge rubber bearing pad or bridge neoprene bearings has been widely used in bridge construction, hydropower engineering and building anti-seismic facilities. Compared with the original steel bearing, neoprene bearing pads have the advantages of simple structure, convenient installation, steel saving, low price, simple maintenance, easy replacement, etc. Moreover, elastomeric laminated bearings has low building height, which is beneficial to bridge design and cost reduction; Elastomeric bearing pad has good isolation effect and can reduce the impact of live load and seismic force on buildings.

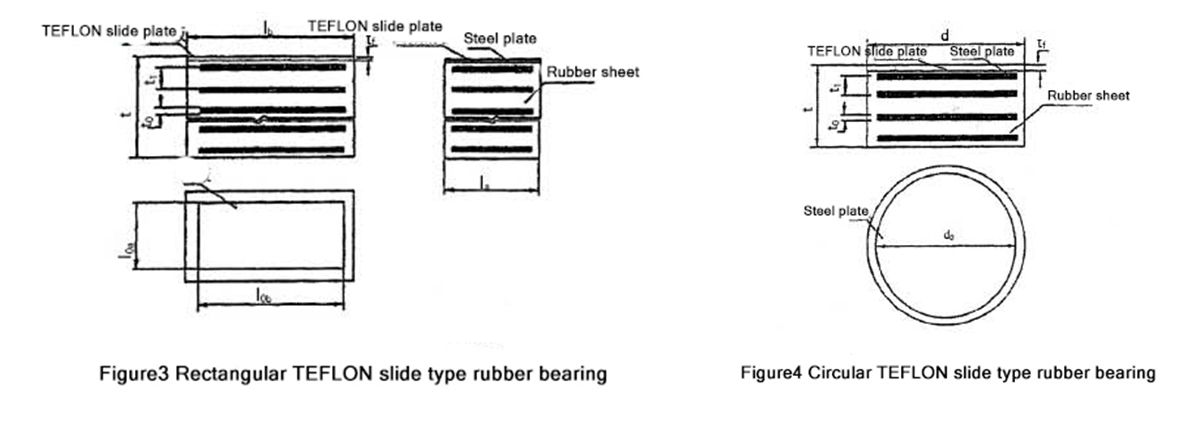

PTFE sliding bearing pad

(1) Features of PTFE bearing pad

PTFE sliding bearing pad is made by bonding a layer of 2-3mm thick PTFE plate on the ordinary elastomeric laminated bearings. In addition to the vertical stiffness and elastic deformation of ordinary elastomeric reinforced bearings, which can withstand vertical load and adapt to the rotation of beam end, the low friction coefficient between tetrafluoroethylene and stainless steel plate at the beam bottom (μ ≤ 0.03) can make the horizontal displacement of bridge superstructure unrestricted.

(2) Application of PTFE bearing pad

The PTFE rubber bearing is suitable for large displacement bridges with large span, multi span continuous, simply supported beam continuous plate and other structures. PTFE bearing pad can also be used as the sliding block in the pushing of continuous beam and the transverse movement of T-shaped beam. The application of rectangular and circular PTFE sliding bearing pad is the same as that of rectangular and circular ordinary plate rubber bearings.

2. Technical requirements

1) Design requirements

The design parameters, design requirements and inspection requests of elastomeric reinforced bearings will be depended on EN, ASTM and ISO standards.

2) Mechanical properties

| Measured tangent value of rotation angle | Concrete bridge | ≥ 1/300 |

| Steel bridge | ≥ 1/500 | |

| Measured friction coefficient between PTFE plate and stainless steel surface(when silicone grease is added) | ≤ 0.03 | |

E1, G1, G2, Ru Will be according to project design requests.

3) The minimum thickness of PTFE sheet bonded with PTFE slide plate should comply with the following table regulations.

| Rectangular elastomeric bearing | Round elastomeric bearing | ||

| Long side range | thickness | Diameter range | thickness |

| ≤500 | 2 | ≤500 | 2 |

| >500 | 3 | >500 | 3 |

4)Rubber material physical properties

| NO. | TEST ITEM | TECHNOLOGY REQUIREMENT | UNIT | |||

| Natural rubber | Polychloroprene rubber | |||||

| 1 | HARDNESS (SHORE A) | 60±5 | 60±5 | HD | ||

| 2 | TENSILE STRENGTH | ≥18 | ≥16 | MPA | ||

| 3 | ELONGATION AT BREAK | ≥450 | ≥400 | % | ||

| 4 | COMPRESSION SET | 70℃×24H | ≤30 | ≤20 | % | |

| 23℃×168H | ≤20 | ≤15 | % | |||

| 5 | PEELING STRENGTH OF RUBBER BONDED TO STEEL | ≥10 | ≥10 | KN/M | ||

| 6 | BRITTLENESS TEMPERATURE | ≤-50 | ≤-40 | ℃ | ||

| 7 | OZONE AGING(50PPHM, 20%ELONGATION, 40℃×96H) | NO CREAK | NO CREAK | --- | ||

| 8 | HOT AIR AGING TEST | Testing conditions | 70x168 | 100x70 | ℃Xh | |

| Reduction of tensile strength | -15 | -15 | % | |||

| Reduction of elongation at break | -20 | -40 | % | |||

| Hardness changeable range | -5,+10 | 0,+10 | IRHD | |||

| 9 | Applicable temperature range | -40-+60 | -25-+60 | ℃ | ||

As a professional elastomeric bearings supplier, Yongxi provides high performance elastomeric bearing pad and bridge elastomeric bearings with custom sevice and strictly controlled quality. If you are considering to buy laminated neoprene bearings or rubber bearing pad with factory supply price, welcome to contact us for detailed information!

3. Installation of rubber bearing pads

Installation steps for bridge rubber bearings:

1) Stone top chiseling and sorting: manual chiseling with an iron chisel, the specific degree of chiseling should comply with the relevant regulations of "Bridge Concrete Construction" for construction joint treatment.

2) Measurement and setting out: According to the center position of the support indicated on the planning map, draw the vertical and horizontal axes on the support and pad stone, and mark the control elevation of the support on the pier and abutment.

3) Leveling and repair: Clean the pad stones on the pier and abutment, and then use dry and hard cement mortar to repair and level the defects on the bearing surface, ensuring that the top elevation meets the design requirements.

4) Mixing epoxy mortar

(1) After drying the fine sand, sequentially heat the fine sand, epoxy resin, dibutyl ester, and xylene in an iron pot and mix evenly.

(2) Strictly configure according to the proportion of epoxy mortar, and the strength should not be lower than the design rules. If there are no design regulations, it should not be lower than 40MPa.

(3) Before bonding the bearing, put Ethylenediamine into the mortar and mix it evenly. Ethylenediamine is the curing agent, which cannot be placed too early or too much to prevent the mortar from curing too early and affecting the bonding quality.

5) Support installation

(1) Confirm the bridge bearing pads according to the design requirements and relevant national standards before installing the support.

(2) Before installing the bridge bearing, details such as the axis, elevation, and flatness of the bridge abutment and pier column cover beam should be rechecked.

(3) The bearing pad is installed after the leveling layer mortar has hardened; When bonding, it is best to first bond the bearings at both ends of the bridge abutment and pier column cap beam. After checking the flatness and elevation, hang a reference line to install other bearings.

(4) When the bridge abutment and pier column cover beams are long, the benchmark bearings should be encrypted to avoid elevation errors exceeding the standard.

(5) When bonding, the mortar should be spread and compacted first, and then the rubber bearing pads should be positioned according to the elevation. The vertical and horizontal axes on the bridge pad should correspond to the vertical and horizontal axes of the pad stone.

(6) Strictly control the flatness of the elastomeric bearing pads, and each bearing must be measured diagonally with an iron level. If any errors exceed the standard, they should be adjusted in a timely manner.

(7) The contact between the bridge bearing and the bearing pad surface should not be empty. For example, when placing a steel pad on the supporting surface, the steel pad should be pre embedded during the construction of the bridge abutment and pier column cover beam, and exhaust holes should be set on the steel plate to ensure that the concrete at the bottom of the steel pad is poured tightly.

The above is an introduction to the detailed steps for installing bridge rubber bearings

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.